What is a Pi heater?

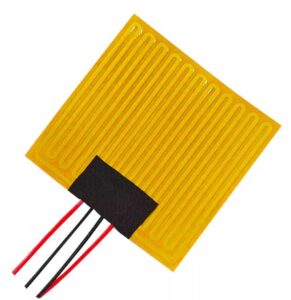

What is a Pi heater? Pi heater(short for polyimide heater), also known as Kapton heater, is a type of temperature control system that uses a combination of proportional and integral control algorithms to maintain a consistent temperature in a heating system.

One property of a Pi heater is that it can respond quickly to changes in the desired temperature setpoint, as the proportional control component will adjust the heating output in proportion to the difference between the setpoint and the actual temperature. Additionally, the integral control component ensures that any small discrepancies between the setpoint and the actual temperature are corrected over time, helping to maintain a stable and accurate temperature.

Another property of a Pi heater is that it can be tuned to provide optimal temperature control for a specific application. By adjusting the proportional and integral control parameters, the response time and stability of the temperature control system can be optimized to meet the needs of the particular heating application.

Overall, the properties of a Pi heater make it a reliable and effective tool for maintaining precise temperature control in a wide range of industrial, scientific, and engineering applications.

What’s the parameter of a Pi/Polyimide heater?

There are several parameters that are important when specifying a polyimide heater. Here are some of the key parameters to consider:

Voltage and Power Rating: Pi heaters typically operate on low voltage DC power, typically in the range of 12-24V. The power rating of a polyimide heater will depend on its size and the desired temperature range.

Temperature Range: Pi heaters can typically operate at temperatures up to 250°C or higher, depending on the materials used and the design of the heater.

Watt Density: This is the amount of power that is delivered per unit area of the Pi heater. Higher watt density heaters will generate more heat, but may require more careful thermal management to avoid hot spots and thermal runaway.

Resistance: The resistance of the Pi heater is an important factor in determining the current draw and power consumption of the heater. It can also affect the distribution of heat across the surface of the heater.

Dimensions: The size and shape of the Pi heater will depend on the specific application and the available space. It is important to consider the dimensions of the heater when designing a system.

Lead Wire Configuration: The lead wire configuration of the heater can affect its ease of use and installation. Some heaters may have pre-attached lead wires, while others may require soldering or crimping of connectors.

What’s the application of Polyimide heater/Pi heater?

- Medical Devices: Polyimide heaters are used in medical devices such as warming blankets, heating pads, and warming cabinets. They provide a gentle and uniform heat source that can help maintain patient body temperature during surgical procedures or other medical treatments.

- Aerospace: Polyimide heaters are used in aerospace applications to provide uniform heating in areas such as fuel tanks, cabin heaters, and avionics. They are lightweight, flexible, and can be customized to fit specific shapes and sizes.

- Laboratory Equipment: Polyimide heaters are used in laboratory equipment such as ovens, incubators, and furnaces. They provide precise and consistent heating for experiments and processes that require controlled temperatures.

- Automotive: Polyimide heaters are used in automotive applications to defrost windows, heat seats, and warm engine components. They are resistant to high temperatures, chemicals, and abrasion, making them ideal for use in harsh environments.

- Consumer Electronics: Polyimide heaters are used in consumer electronics such as smartphones, tablets, and laptops to prevent moisture buildup and maintain battery performance in cold temperatures. They are thin, flexible, and can be customized to fit specific device shapes and sizes.

- Food Service: Polyimide heaters are used in commercial food service equipment such as warming trays, heat lamps, and food display cases. They provide a reliable and energy-efficient heat source to keep food at the ideal serving temperature.

- Printing: Polyimide heaters are used in printing equipment such as digital printers and offset printing presses. They provide a uniform and controlled heat source to dry ink and other printing materials quickly and efficiently.

- Analytical Instruments: Polyimide heaters are used in analytical instruments such as gas chromatography and mass spectrometry systems. They provide a precise and consistent heating source to help separate and analyze complex chemical compounds.

- Industrial Equipment: Polyimide heaters are used in various industrial equipment such as chemical reactors, valves, and pumps. They provide a reliable and uniform heat source to maintain the optimal temperature of fluids and gases.

- Energy: Polyimide heaters are used in energy applications such as solar panels, fuel cells, and batteries. They provide a heat source to improve the efficiency and performance of these devices.

- Textiles: Polyimide heaters are used in textile production to heat rollers and plates to ensure proper fabric tension, improve adhesion, and maintain uniform dyeing.

- Packaging: Polyimide heaters are used in packaging production to heat-seal various materials such as plastics, films, and foils. They provide a reliable and consistent heat source to ensure a secure and airtight seal.

- 3D Printing: Polyimide heaters are used in 3D printing equipment to heat the printing bed to the ideal temperature to ensure proper adhesion of the printed material.

- Agriculture: Polyimide heaters are used in agricultural applications to provide warmth to plants, seeds, and soil to promote growth and prevent frost damage.

- Defense and Military: Polyimide heaters are used in defense and military equipment such as satellite systems, radar systems, and missile guidance systems. They provide a reliable and flexible heating solution in harsh environments.

In summary, polyimide heaters are a versatile heating solution used in various industries and applications where flexibility, durability, and precise temperature control are required.