Kapton heater with NTC thermistor description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 200 ℃

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is kapton heater with NTC thermistor?

A Kapton heater with an NTC thermistor refers to a heating system that incorporates a Kapton heater element and an NTC thermistor for temperature sensing and control.

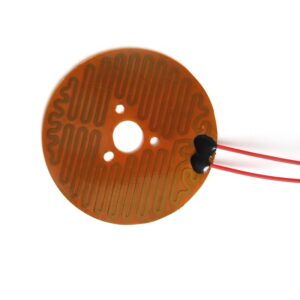

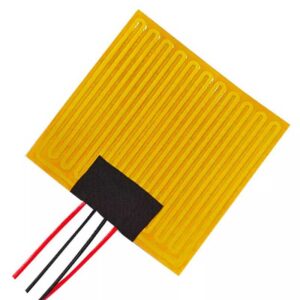

Kapton Heater: A Kapton heater is a type of flexible heating element made from a thin film of Kapton, a high-temperature-resistant polyimide material. Kapton heaters are known for their ability to withstand high temperatures, excellent thermal stability, and flexibility. They can be custom-designed into various shapes and sizes to fit specific applications.

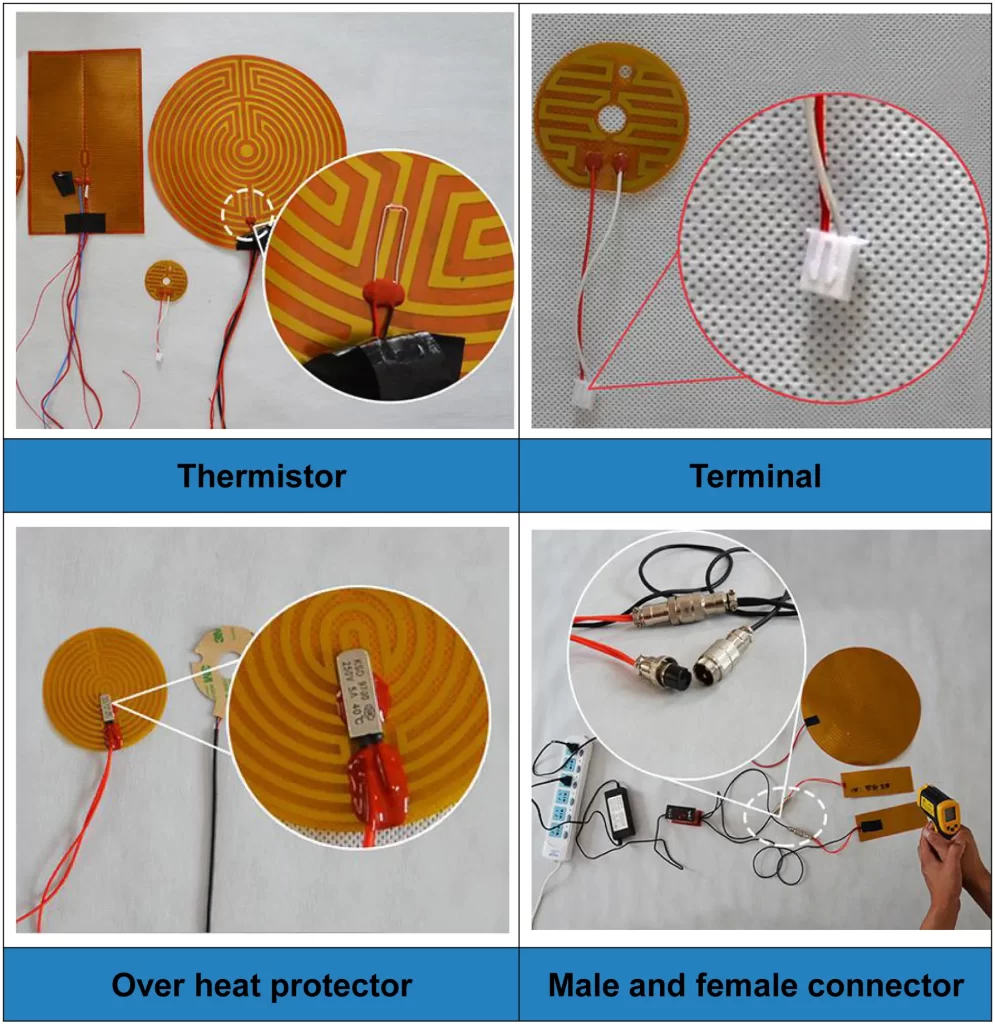

NTC Thermistor: An NTC thermistor, also known as a Negative Temperature Coefficient thermistor, is a temperature sensing device that exhibits a decrease in electrical resistance as the temperature increases. NTC thermistors are typically made from metal oxides and are known for their high sensitivity and accuracy in temperature measurement. They are commonly used in applications where precise temperature control is required.

In a Kapton heater with an NTC thermistor setup, the NTC thermistor is used to monitor the temperature of the system. It is usually placed in close proximity to the Kapton heater to accurately sense the temperature. As the temperature changes, the electrical resistance of the NTC thermistor varies accordingly.

The NTC thermistor is connected to a thermostat or temperature control circuit, which measures the resistance of the thermistor and translates it into temperature values. The thermostat circuit compares the measured temperature with a desired setpoint temperature. Based on this comparison, the circuit regulates the power supplied to the Kapton heater.

If the measured temperature is below the setpoint, indicating the need for heating, the thermostat circuit increases the power supplied to the Kapton heater. Conversely, if the measured temperature exceeds the setpoint, the power to the Kapton heater is reduced or turned off. This control mechanism allows the system to maintain the desired temperature with precision.

In summary, a Kapton heater with an NTC thermistor combines the heat-generating capabilities of a flexible Kapton heater with the temperature sensing and control provided by an NTC thermistor. This configuration enables accurate and efficient heating for applications that require precise temperature control.

How does the kapton heater with NTC thermistor work?

The Kapton heater with an NTC thermistor works based on the principle of temperature sensing and feedback control. Here’s a step-by-step explanation of how it operates:

Temperature Sensing: The NTC thermistor, which is typically positioned in close proximity to the Kapton heater, continuously measures the temperature of the system. As the temperature changes, the electrical resistance of the NTC thermistor also changes. The NTC thermistor is specifically designed to have a negative temperature coefficient, meaning its resistance decreases as the temperature increases.

Temperature Control Circuit: The NTC thermistor is connected to a temperature control circuit or thermostat. This circuit contains components such as an amplifier, comparator, and feedback mechanism.

Desired Temperature Setpoint: The temperature control circuit is pre-set with a desired temperature setpoint, representing the target temperature for the system.

Comparison: The temperature control circuit compares the resistance of the NTC thermistor, which corresponds to the measured temperature, with the desired temperature setpoint. This comparison determines whether the system needs more or less heat to reach and maintain the desired temperature.

Feedback Control: Based on the comparison result, the temperature control circuit adjusts the power supplied to the Kapton heater. If the measured temperature is lower than the setpoint, indicating the need for heating, the circuit increases the power supplied to the Kapton heater. This causes the Kapton heater to generate more heat and raise the temperature.

Temperature Equilibrium: As the temperature rises, the NTC thermistor detects the change and adjusts its resistance accordingly. The temperature control circuit continuously monitors the temperature and adjusts the power supplied to the Kapton heater to maintain a balance between the measured temperature and the desired setpoint.

Temperature Maintenance: The temperature control circuit keeps regulating the power supplied to the Kapton heater, ensuring that the temperature remains close to the desired setpoint. If the measured temperature exceeds the setpoint, the circuit reduces or cuts off the power to the Kapton heater, preventing overheating.

By utilizing the NTC thermistor’s temperature sensing capabilities and the feedback control provided by the temperature control circuit, the Kapton heater with an NTC thermistor can achieve precise temperature control. This makes it suitable for applications where maintaining specific temperatures is crucial, such as in electronics, laboratory equipment, and industrial processes.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–290℃

|

|

Cable conductor

|

Silicone insulated leads

|

Configuration of the Kapton heater

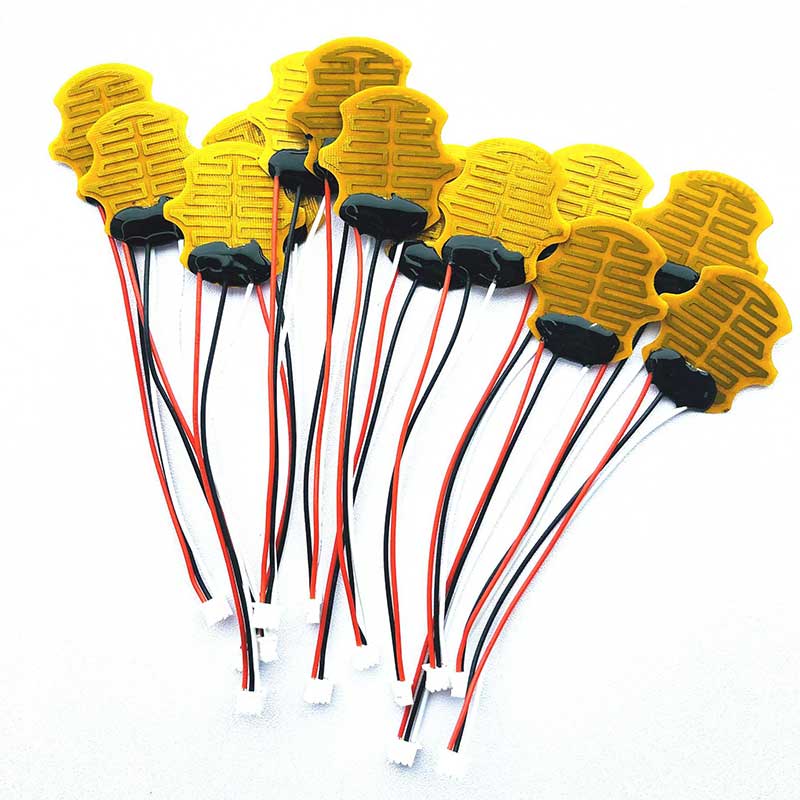

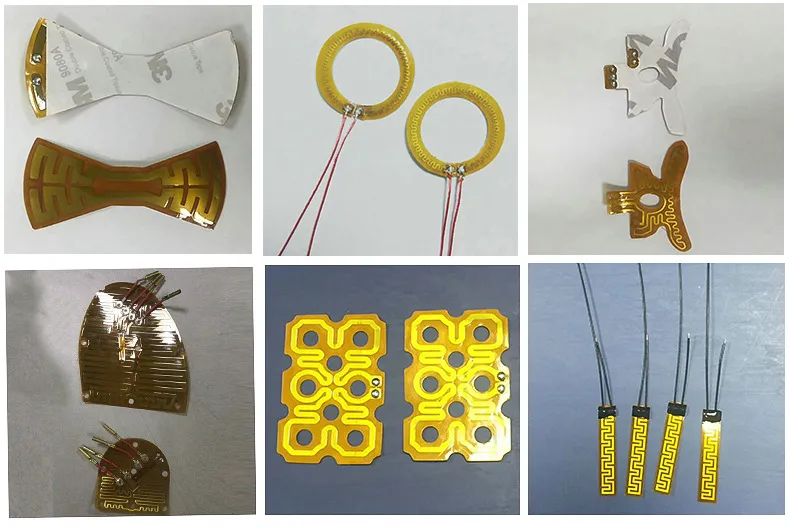

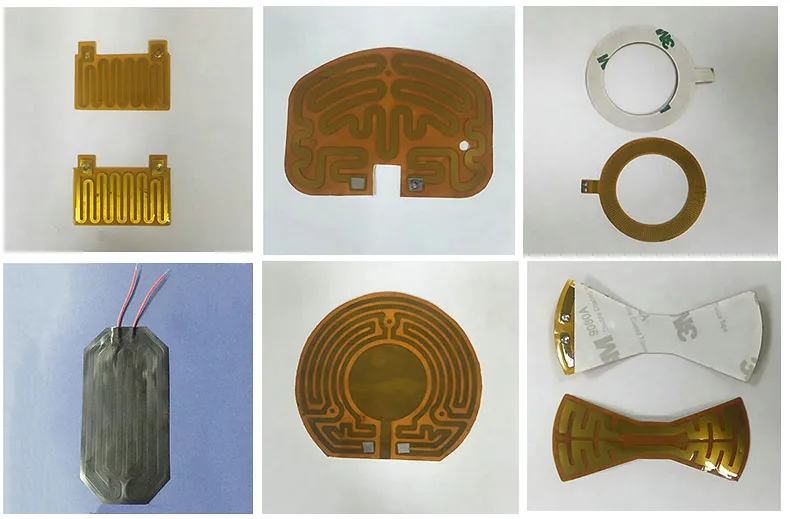

Kapton heater in different shapes

Kapton heater Application

Our Factory

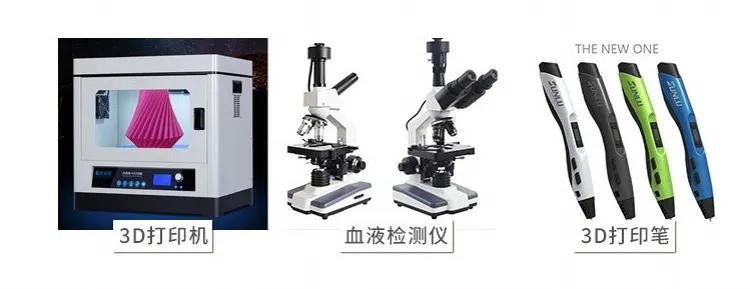

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

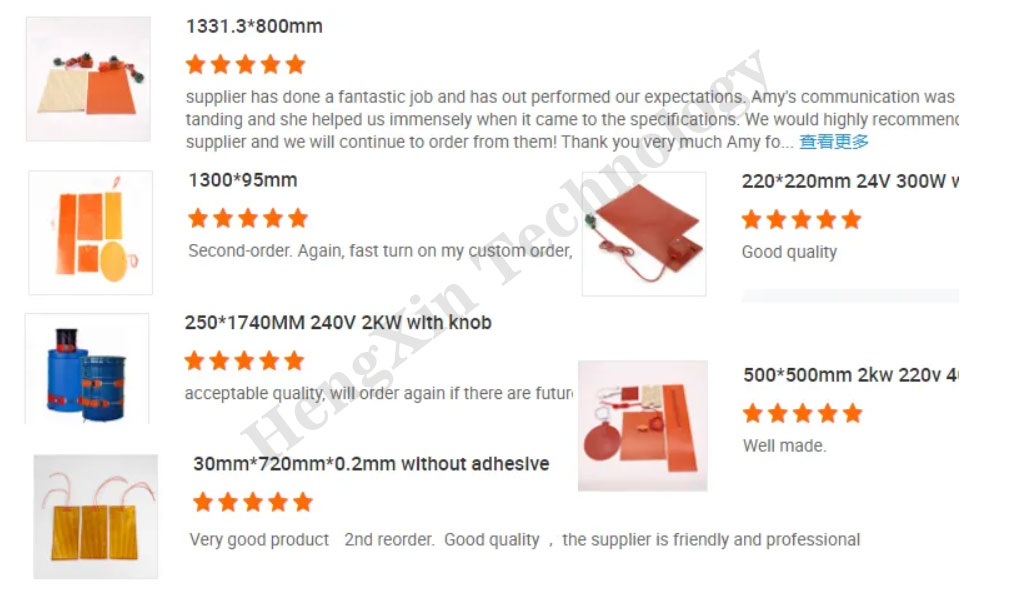

Customers Feedback for our products

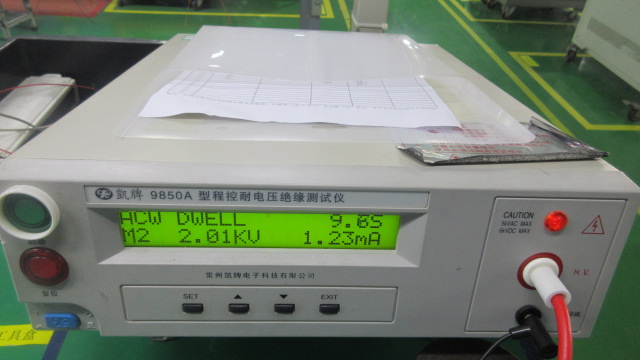

Certificates of the heating elements

Other products you may interest:

Kapton Heater leads the heating industry by offering energy-efficient heating solutions for modern industries. Our heating solutions, which include infrared heaters, radiant heaters, and heating elements, incorporate temperature control technology for precise and accurate heating. Our commitment to energy efficiency is evident in our eco-friendly heating solutions that minimize energy consumption. Our cutting-edge products and advanced technology are revolutionizing industrial heating. At Kapton Heaters, we are dedicated to delivering reliable, efficient, and effective heating solutions. Trust us for all your heating needs. Our Kapton heaters are backed by a 50,000-hour warranty in normal working conditions, and we offer various connector and temperature control options to suit your preferences.

Our team at Kapton Heater is composed of highly skilled and experienced professionals who are passionate about providing excellent customer service. We work closely with our clients to understand their unique heating needs and develop customized solutions that meet their requirements. Whether you’re looking to heat a small laboratory or a large industrial facility, we have the expertise and resources to deliver optimal heating solutions.

At Kapton Heater, we prioritize safety and compliance with industry standards. Our heating solutions are manufactured using high-quality materials and adhere to rigorous safety protocols to ensure safe and reliable operation. We also offer installation and maintenance services to ensure that your heating solutions are operating at their best.

Choose Kapton Heater for all your heating needs and experience the benefits of our energy-efficient, eco-friendly, and reliable heating solutions.

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]