High Temperature PI Heater Element description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 180 ℃

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is PI heater?

A PI film heater refers to a heating element that utilizes a Polyimide (PI) film as its base material. Polyimide is a versatile polymer known for its high-temperature resistance, excellent electrical insulation properties, and flexibility. PI film heaters are commonly used in various applications, including electronics, aerospace, automotive, and medical industries.

The PI film heater consists of a thin film of Polyimide with integrated heating elements. These heating elements are typically made of conductive materials like etched foil or printed resistive traces. The Polyimide film provides electrical insulation and mechanical support for the heating elements.

PI film heaters are flexible and can conform to various shapes and surfaces, making them suitable for applications where space is limited or a custom fit is required. They offer uniform heat distribution and rapid heating capabilities.

How does PI Heater Work?

A PI heater, or a Polyimide film heater, works based on the principle of resistive heating. The Polyimide film, which serves as the base material, contains integrated heating elements made of conductive materials.

When an electric current is passed through the heating elements, they resist the flow of electricity, causing them to heat up. This heat is then transferred to the surrounding environment or the object in contact with the PI heater.

The Polyimide film in the heater acts as an insulator, preventing electrical current from directly contacting the object being heated. It also provides mechanical support and flexibility to the heater, allowing it to conform to various shapes and surfaces.

The resistance of the heating elements determines the amount of heat generated. By controlling the electrical current flowing through the heater, the temperature output can be adjusted to achieve the desired level of heating.

What is PI Heater?

The Thermal PI Heater is a type of heating system that utilizes a proportional-integral (PI) control algorithm to regulate temperature. This control algorithm adjusts the power supplied to the heater based on the difference between the desired temperature and the actual temperature.

The proportional component responds to the current error (the difference between desired and actual temperature), while the integral component accumulates past errors to compensate for any steady-state errors. This results in more precise temperature control compared to simpler control methods.

Thermal PI Heaters are commonly used in various applications where precise temperature control is required, such as industrial processes, laboratories, and environmental chambers. They offer efficient heating solutions with minimal temperature fluctuations, making them ideal for maintaining consistent temperatures in sensitive environments.

Efficiency: Thermal PI Heaters are designed for efficiency, as they adjust the power supplied based on the temperature error. This means they only consume the necessary amount of energy to maintain the desired temperature, reducing energy waste and operating costs.

Versatility: These heaters can be used in a wide range of applications, from heating liquids and gases in industrial processes to maintaining stable temperatures in research and development settings.

Temperature Range: Depending on the specific design and components, Thermal PI Heaters can operate within a wide temperature range, from ambient temperatures to very high temperatures required for certain industrial processes.

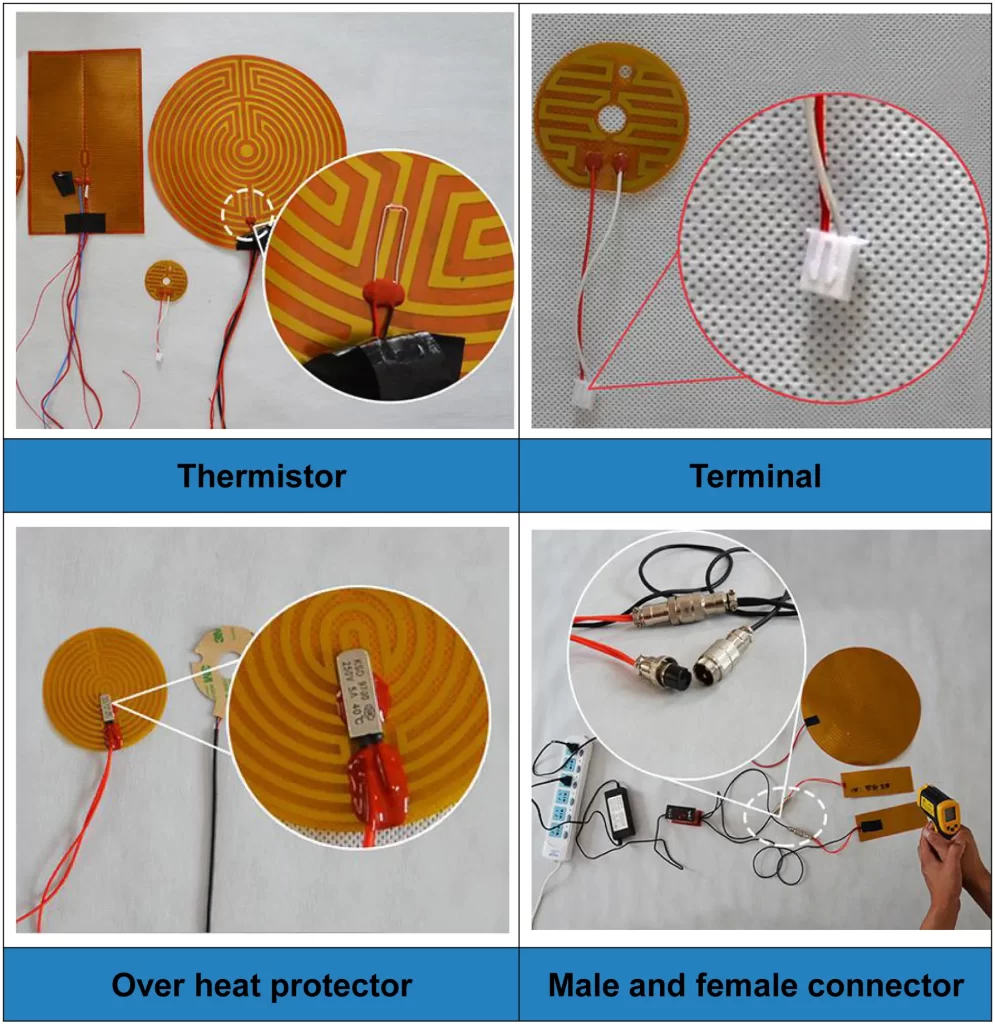

Control Interface: Many Thermal PI Heaters come with user-friendly control interfaces, allowing operators to set desired temperatures, monitor temperature levels, and adjust heating parameters as needed.

Safety Features: To ensure safe operation, Thermal PI Heaters often incorporate built-in safety features such as temperature sensors, overheat protection, and fail-safe mechanisms to prevent overheating or other hazardous conditions.

Reliability: With their advanced control algorithms and robust construction, Thermal PI Heaters are known for their reliability and durability, providing consistent performance over long periods of operation.

Integration: These heaters can often be integrated into automated systems and controlled remotely, allowing for seamless integration into larger industrial or research setups.

Introduction:

In today’s fast-paced industrial landscape, optimizing efficiency and productivity is essential to stay ahead. When it comes to drying processes, the choice of heating technology can make a significant difference. Enter polyimide heaters – the cutting-edge solution revolutionizing industrial drying operations. Let’s delve into how these advanced heaters can transform your manufacturing processes.

Precise Heat Distribution:

Polyimide heaters are engineered to provide precise and uniform heat distribution across the drying surface. Unlike traditional heating methods, which may result in uneven drying or hotspots, polyimide heaters ensure consistent temperature control. This precision not only improves the quality of dried products but also enhances process reliability.

Versatility and Adaptability:

One of the key advantages of polyimide heaters is their versatility. They can be customized to meet the specific requirements of various drying applications, including coatings, films, textiles, and more. Whether you’re dealing with delicate materials that require gentle drying or robust substrates that demand rapid processing, polyimide heaters can be tailored to suit your needs.

Durability and Longevity:

Industrial environments can be harsh, with exposure to high temperatures, moisture, and chemicals. Polyimide heaters are built to withstand these challenges, thanks to their durable construction and resistance to corrosion and degradation. This ensures a longer lifespan for the heaters, minimizing downtime and maintenance costs.

Energy Efficiency:

In an era of increasing energy costs and environmental awareness, efficiency is paramount. Polyimide heaters excel in this regard, offering superior energy efficiency compared to traditional heating methods. By maximizing heat transfer and minimizing energy waste, these heaters help reduce operating costs and carbon footprint.

Cost-Effective Solution:

Investing in polyimide heaters is not just about improving drying performance – it’s also a smart financial decision. Their long-term reliability, energy efficiency, and minimal maintenance requirements translate to significant cost savings over time. Whether you’re a small-scale operation or a large industrial facility, polyimide heaters offer a cost-effective solution that delivers results.

Conclusion:

Polyimide heaters represent the future of industrial drying technology. With their precise heat distribution, versatility, durability, energy efficiency, and cost-effectiveness, they offer a comprehensive solution for manufacturers seeking to optimize their drying processes. Embrace the power of polyimide heaters and unlock new levels of efficiency and productivity in your operations.

A high-temperature polyimide film heater element is a pivotal component utilized across various industries and scientific domains where precise and reliable heating under extreme conditions is paramount. These heater elements are crafted from polyimide films, renowned for their exceptional thermal stability and resistance to high temperatures.

The control system enables efficient temperature regulation by adjusting the power input to the heater element based on feedback from temperature sensors. This control mechanism ensures that the desired temperature set point is maintained with accuracy and stability, even in challenging environments.

Industries such as aerospace, automotive, electronics, and medical devices heavily rely on high-temperature polyimide film heater elements for critical applications like thermal bonding, curing, laminating, and heat sealing. Their ability to deliver uniform heating over large surface areas while withstanding extreme temperatures makes them indispensable in various manufacturing processes.

The versatility and reliability of high-temperature polyimide film heater elements contribute significantly to process efficiency, product quality, and operational safety in industrial settings. Furthermore, their compact and flexible design allows for easy integration into complex systems and equipment, further enhancing their utility across diverse applications.

In conclusion, high-temperature polyimide film heater elements represent a cutting-edge solution for demanding heating requirements, playing a pivotal role in advancing technological innovation and industrial progress.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–180℃

|

|

Cable conductor

|

Silicone insulated leads

|

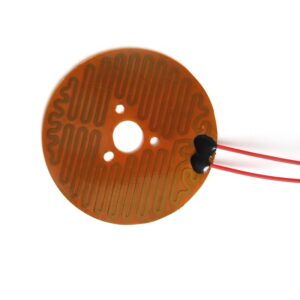

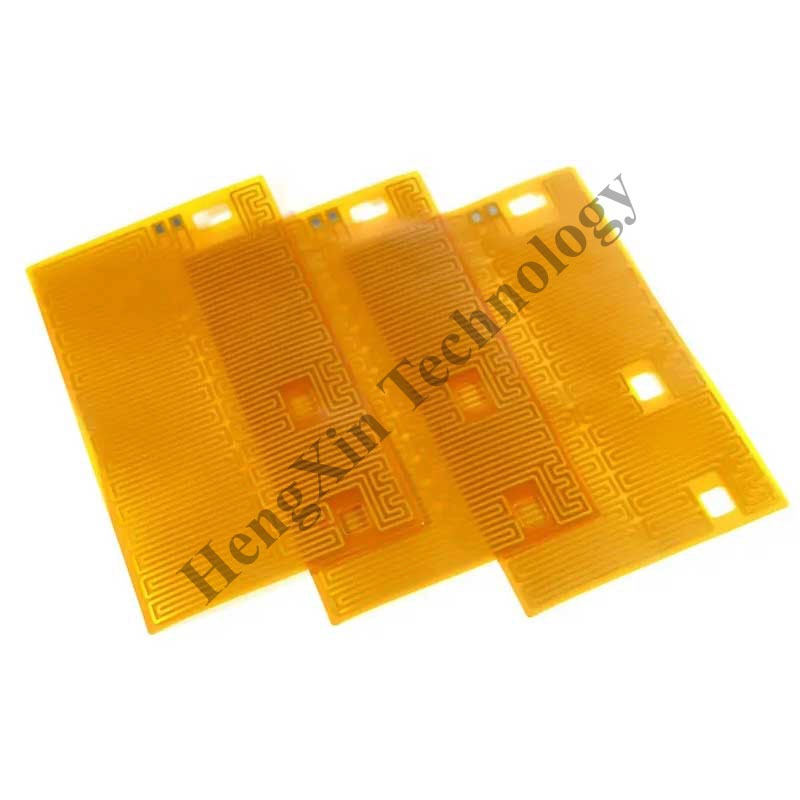

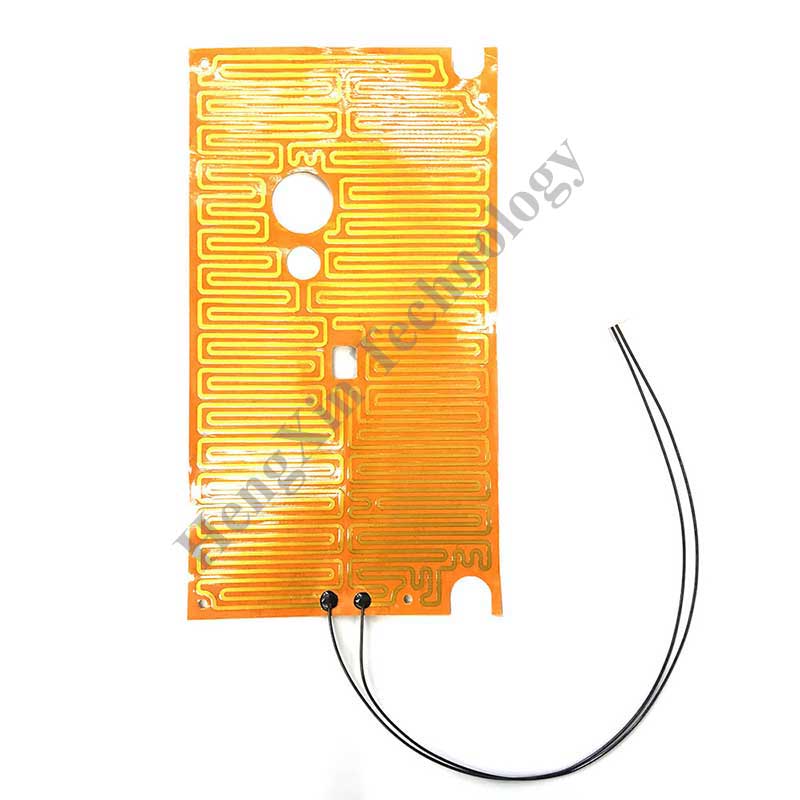

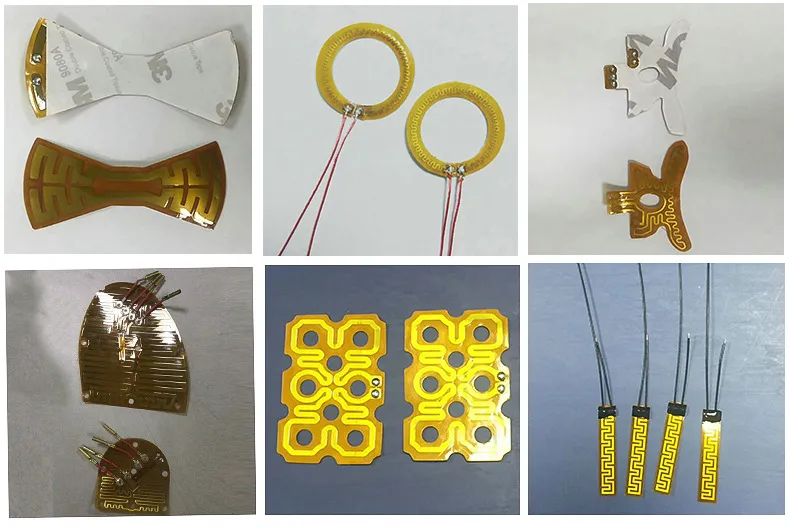

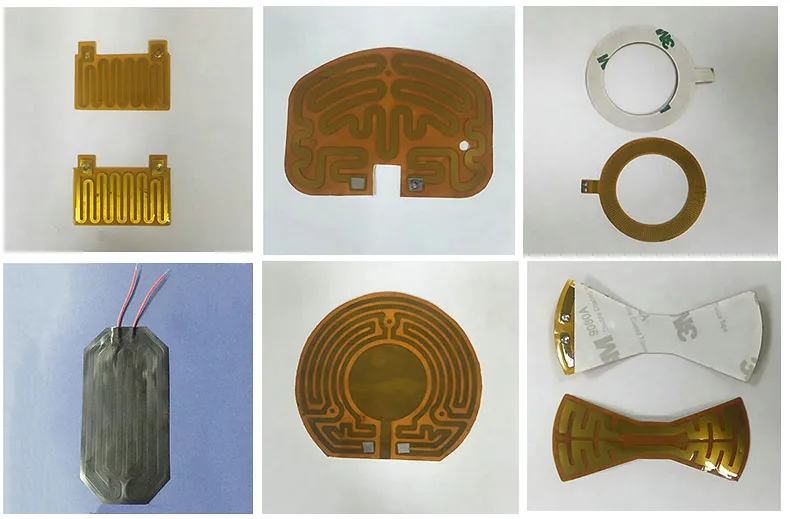

Configuration of the PI heater

PI heaters in different shapes

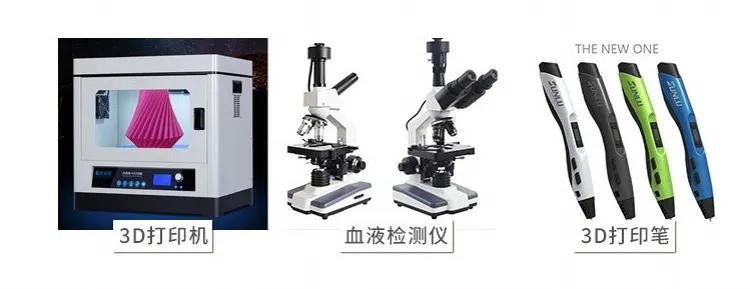

Pi heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

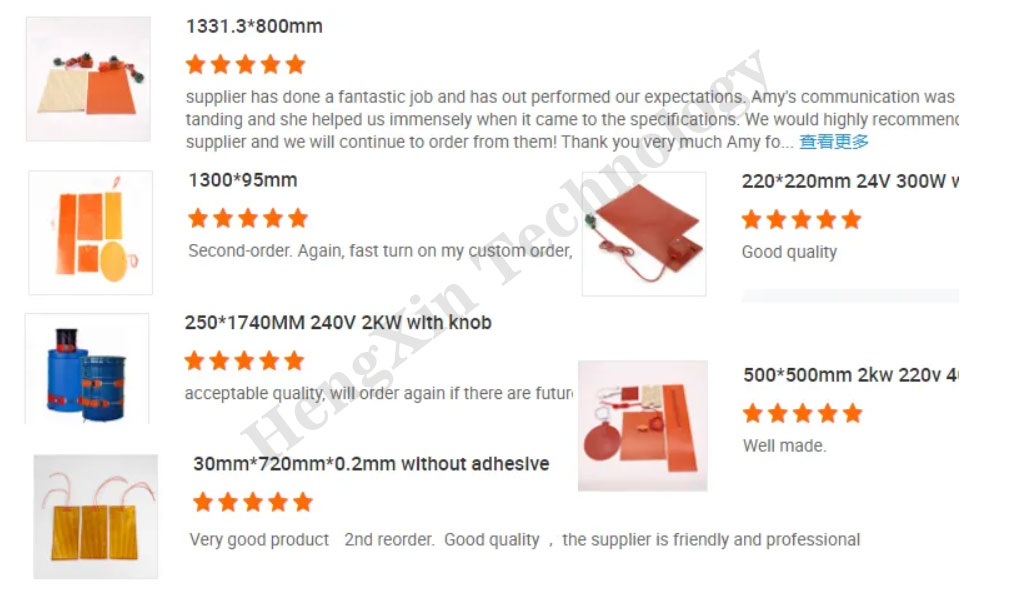

Customers Feedback for our products

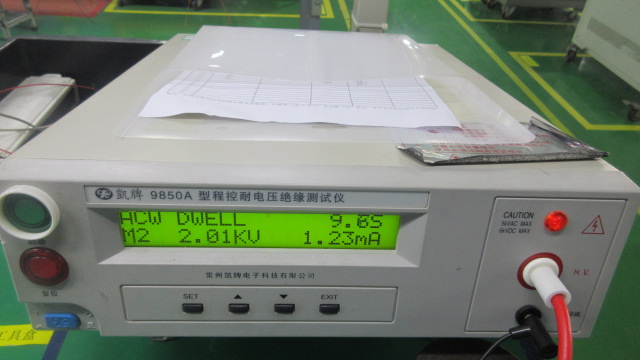

Certificates of the heating elements

Other products you may interest:

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]