Custom Surface Pi Heater description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:40K hours

Working Temperature Range:-30 – 180 ℃

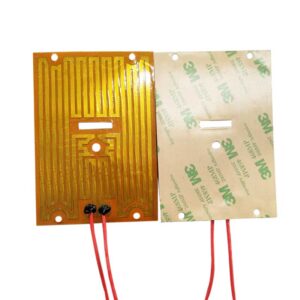

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is Custom Surface Pi Heater ?

A PI film heater refers to a heating element that utilizes a Polyimide (PI) film as its base material.A versatile polymer prized for its exceptional high-temperature resistance, superb electrical insulation characteristics, and flexibility, plays a crucial role in a wide array of industries. PI film heaters, featuring prominently in sectors like electronics, aerospace, automotive, and medicine, have gained popularity due to their efficiency and adaptability.

PI film heaters are crafted from a thin layer of polyimide housing integrated heating components. These heating elements are typically composed of conductive materials, such as etched foil or printed resistive tracks. The polyimide film serves a dual purpose, offering electrical insulation and providing mechanical support to the heating elements.

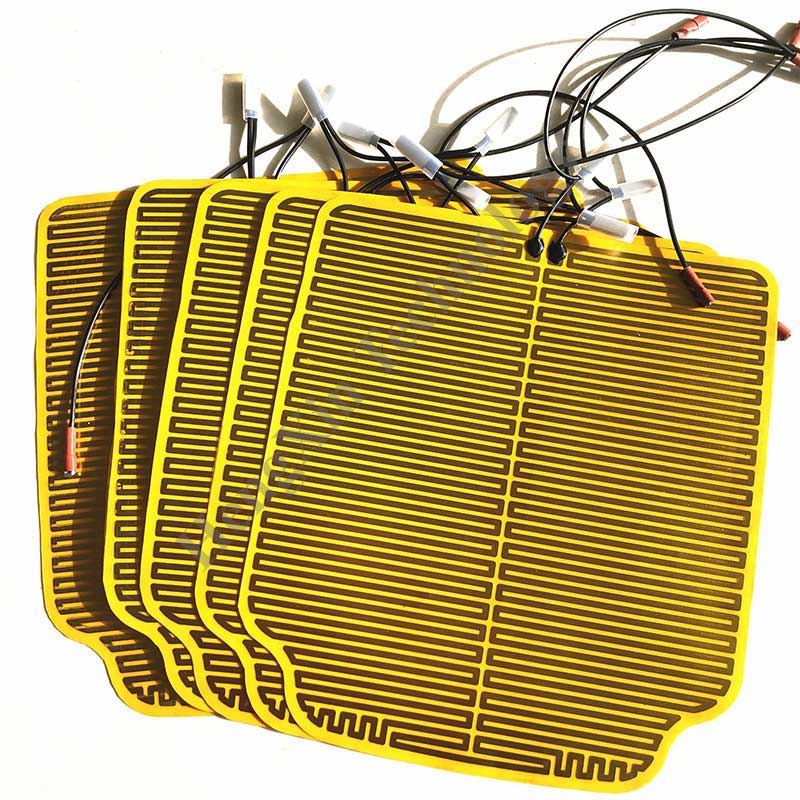

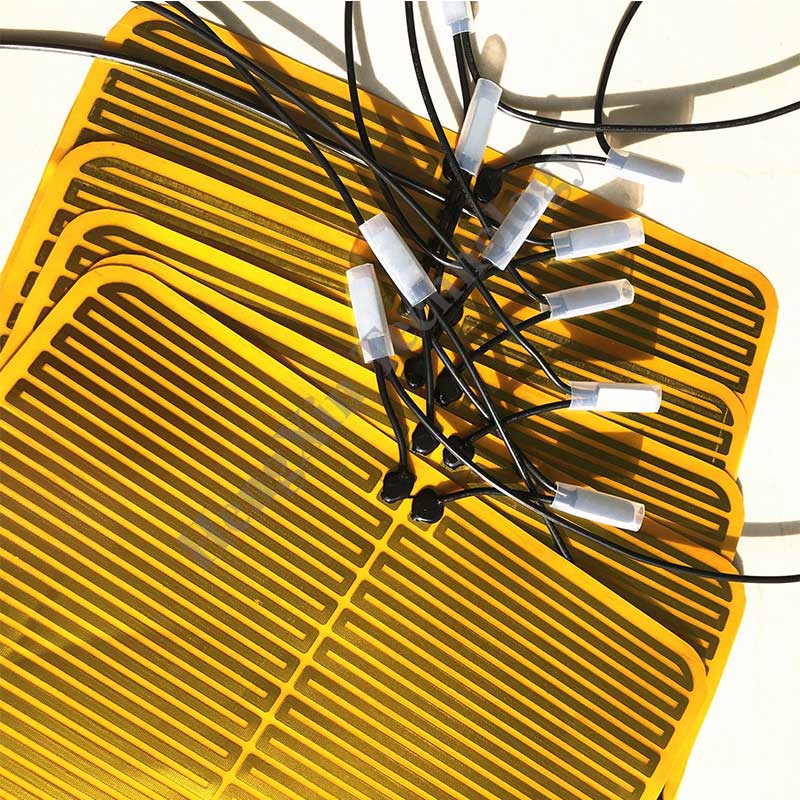

These flexible PI film heaters are particularly valued for their ability to adapt to various shapes and surfaces. This trait makes them an ideal choice for applications where space constraints are a concern, or a custom fit is essential. Additionally, they excel in achieving uniform heat distribution and rapid heating, fulfilling the diverse needs of various industries.

How does Custom Surface Pi Heater Work?

The fundamental design of this heater involves the integration of conductive heating elements within a Polyimide film.

When an electrical current is applied to these heating elements, they naturally resist the flow of electricity, leading to the generation of heat. This heat is then transferred to the surrounding environment or the object that comes into contact with the PI heater.

Crucially, the Polyimide film serves a dual role in the heating process. Firstly, it acts as an insulating barrier, ensuring that electrical current does not make direct contact with the object undergoing heating. Secondly, it provides vital mechanical support and flexibility, enabling the heater to conform to a variety of shapes and surfaces.

The level of heat produced is contingent on the resistance of the heating elements. By carefully controlling the electrical current coursing through the heater, the temperature output can be precisely adjusted to achieve the desired heating level.

What are the Applications of Custom Surface Pi Heater?

PI heaters, or Polyimide film heaters, find applications in various industries and scenarios due to their flexibility, high-temperature resistance, and electrical insulation properties. Some common applications of PI heaters include:

Electronics: PI heaters are used in electronic devices and components to provide localized heating, such as in LCD displays, touchscreens, and circuit boards. They help maintain optimal operating temperatures or prevent moisture accumulation in sensitive electronics.

Aerospace: PI heaters are employed in aerospace applications to prevent ice formation on critical components like wings, sensors, or antennas. They ensure proper functioning and safety of aircraft in cold or icy conditions.

Medical: PI heaters are utilized in medical equipment, diagnostic devices, and laboratory instruments. They help maintain specific temperatures for sample processing, incubation, or patient comfort, ensuring accurate results and reliable performance.

Automotive: PI heaters are found in automotive applications, including defrosting or defogging windshields, heating side mirrors, or preventing fuel line freezing in cold weather.

Industrial: PI heaters are used in industrial settings for applications like curing adhesives, preheating materials for processing, or maintaining consistent temperatures in production processes.

Camera Lenses: PI heaters can be used in camera lenses to prevent fogging or condensation in cold or high-humidity environments. They help maintain the lens temperature above the dew point and ensure clear and unobstructed photography.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–180℃

|

|

Cable conductor

|

Silicone insulated leads

|

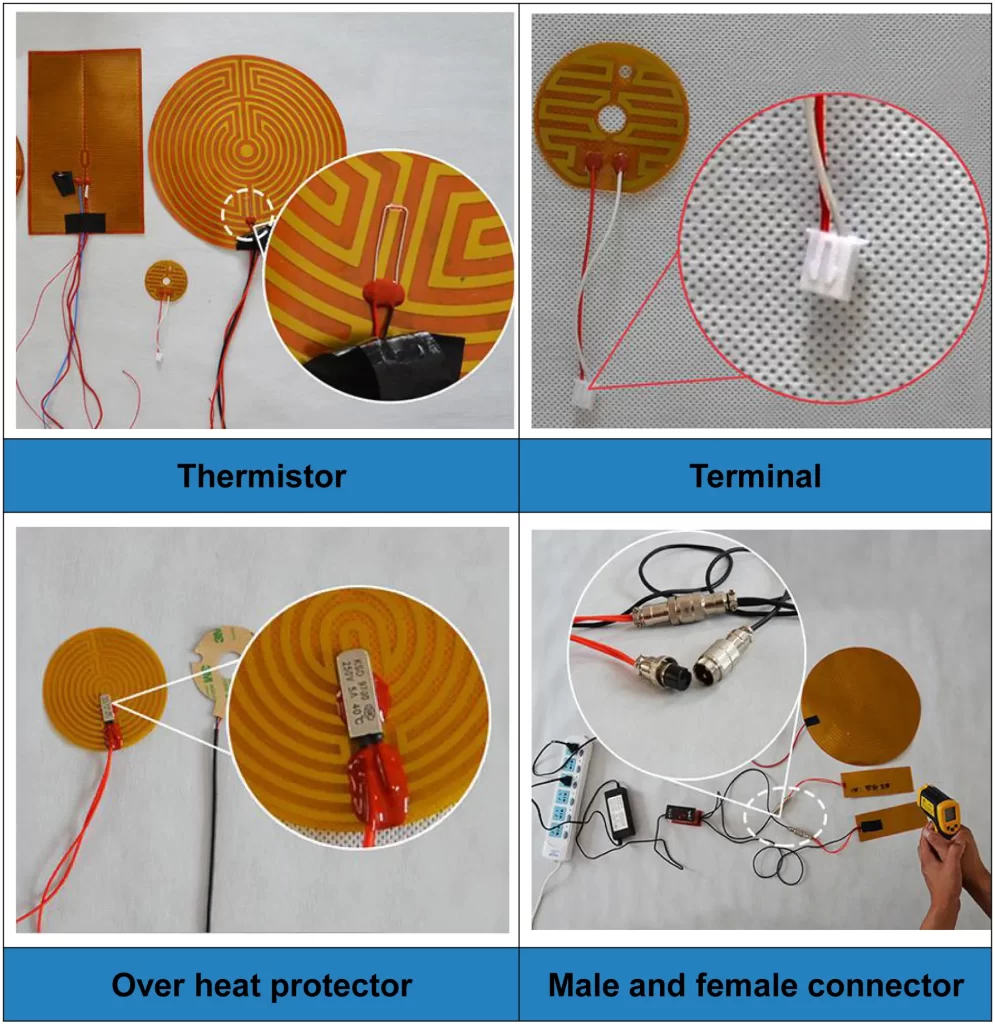

Configuration of the Custom Surface Pi Heater

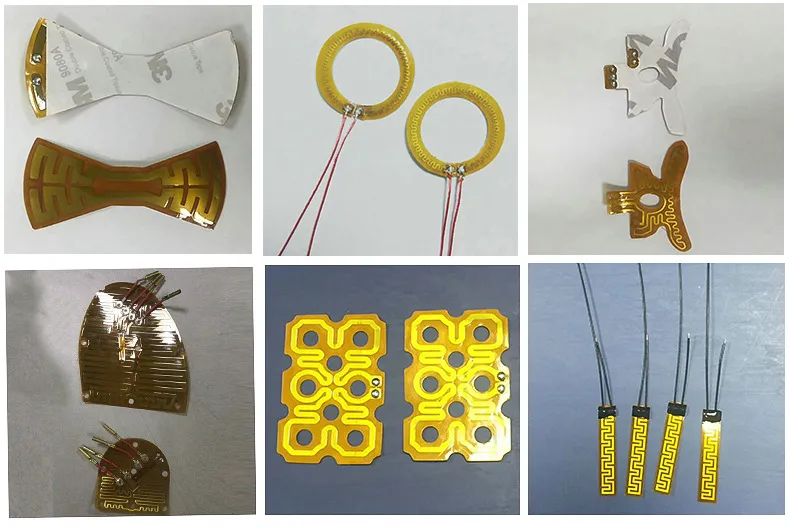

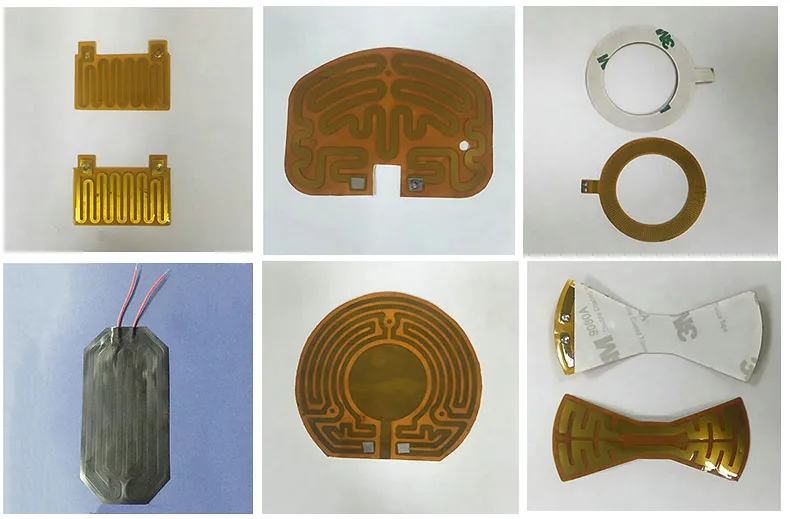

PI heaters in different shapes

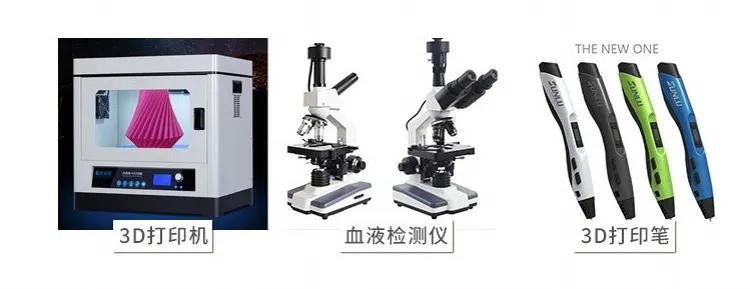

Custom Surface Pi Heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,Pet heater and Silicone heater with customized size and shape, with qualifed products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. 50000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

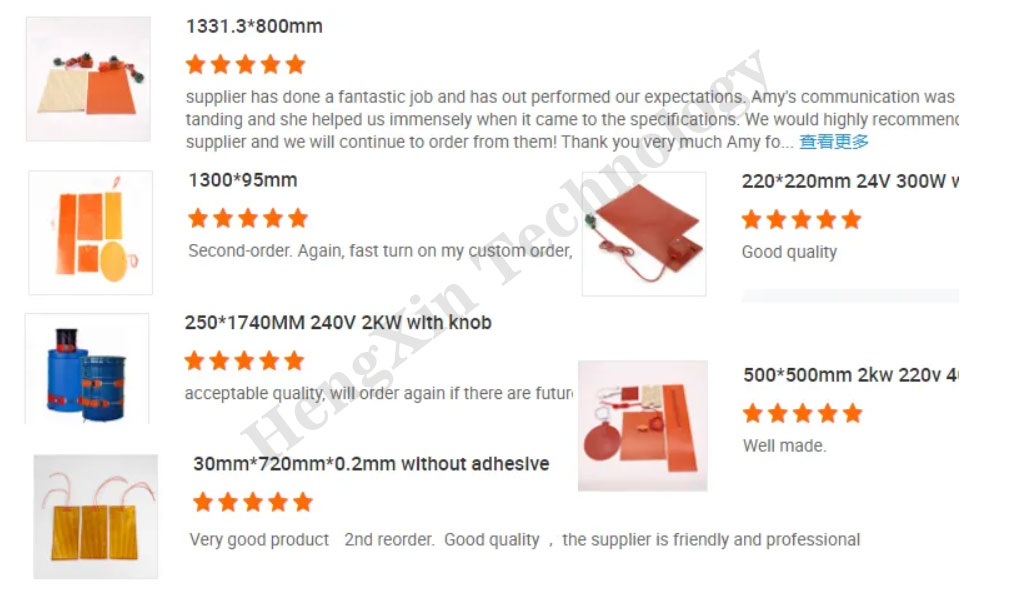

Customers Feedback for our products

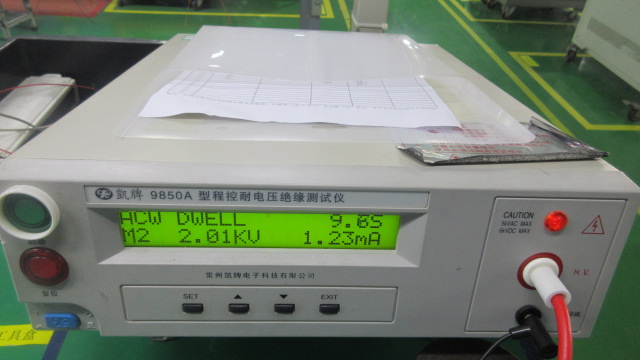

Certificates of the heating elements

Other products you may interest:

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]