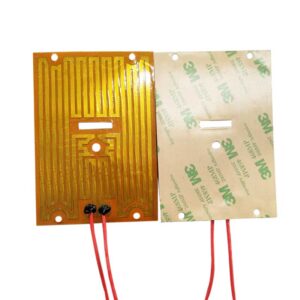

Pi heater with connector description

Applicable Industries:Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

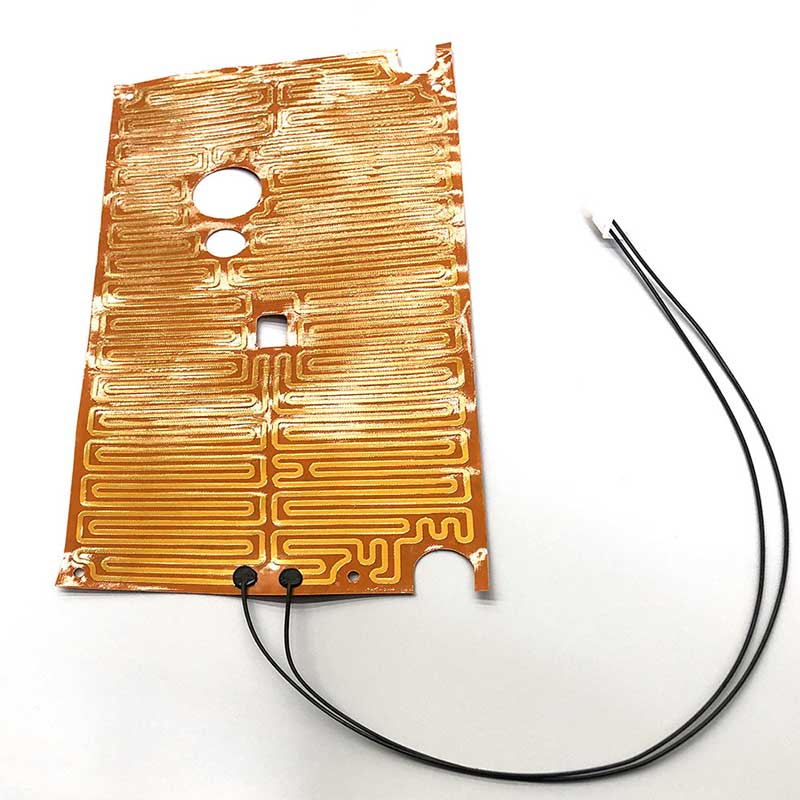

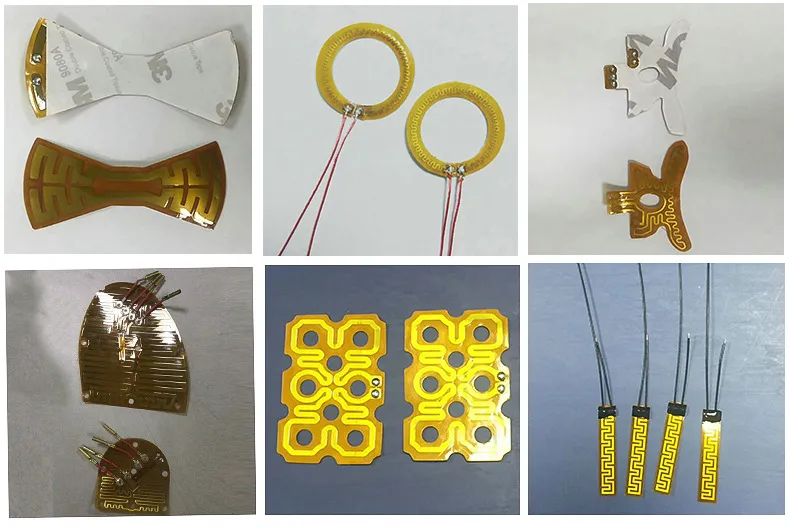

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 200 ℃

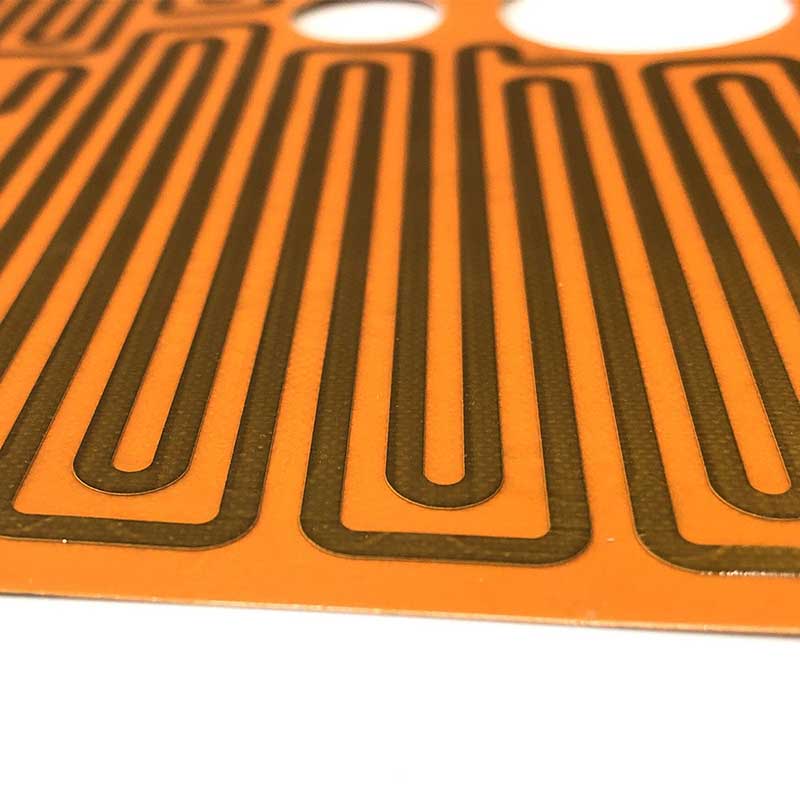

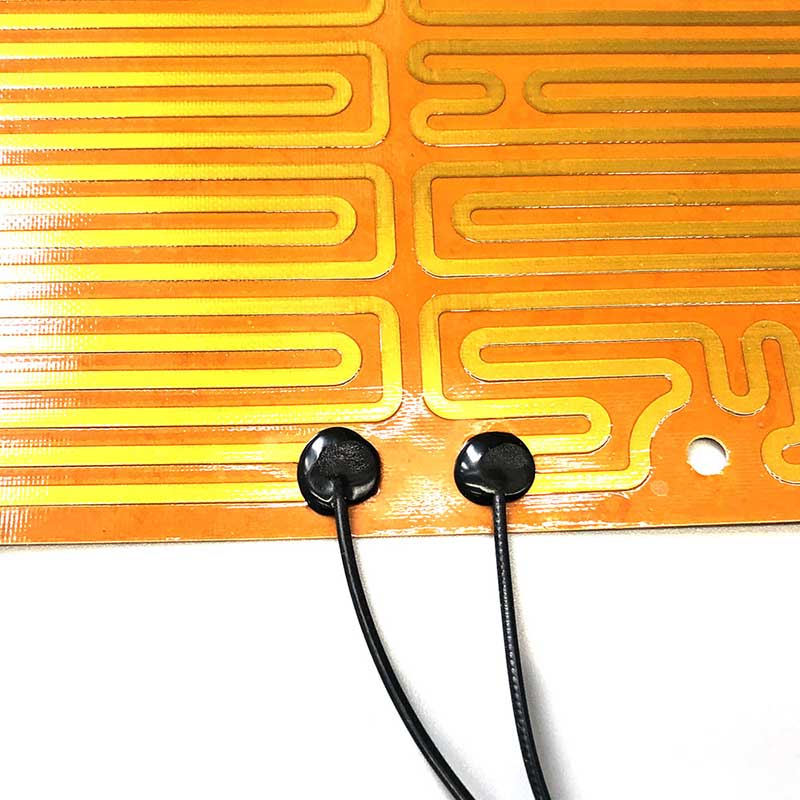

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is a PI /Polyimide Heater?

A PI/Polyimide Heater,also called Kapton Heater is a type of flexible heater that is made using a polyimide film as the substrate and a resistive metal element for heating. Polyimide is a high-performance plastic material that is well-suited for use in high-temperature and harsh environments.

PI/Polyimide heaters are commonly used in applications where space is limited and a flexible, lightweight heating solution is required. They can be designed in a variety of shapes and sizes to fit the specific needs of the application.

PI/Polyimide heaters have a number of advantages over other types of heaters. They are highly durable and can withstand extreme temperatures and environmental conditions. They are also very efficient and can heat up quickly and evenly.

How does PI/Polyimide Heater Work?

Polyimide heaters work on the principle of electrical resistance heating. The heater consists of a thin film of polyimide material, which has a high resistance to electrical current flow. When a voltage is applied across the heater, the electrical current flowing through the polyimide film encounters resistance, and this resistance produces heat.

The heat generated by the polyimide heater is proportional to the amount of electrical current flowing through the heater and the resistance of the polyimide material. The temperature of the heater can be controlled by adjusting the voltage applied to the heater, or by using a temperature control system that regulates the voltage to maintain a set temperature.

What are the Applications of a PI/Polyimide Heater?

Polyimide heaters have a wide range of applications across various industries. Some common applications of polyimide heaters include:

- Medical devices: Polyimide heaters are used in medical devices such as blood warmers, diagnostic equipment, and surgical instruments.

- Aerospace: Polyimide heaters are used in aerospace applications such as satellite thermal control, de-icing systems, and cabin heating.

- Automotive: Polyimide heaters are used in automotive applications such as seat heaters, engine preheating, and diesel fuel filters.

- Electronics: Polyimide heaters are used in electronic applications such as LCD displays, battery heaters, and semiconductor wafer processing.

- Industrial: Polyimide heaters are used in industrial applications such as plastics processing, food processing, and laboratory equipment.

- Defense: Polyimide heaters are used in defense applications such as missile guidance systems and infrared detectors.

- Research: Polyimide heaters are used in research applications such as thermal imaging and materials testing.

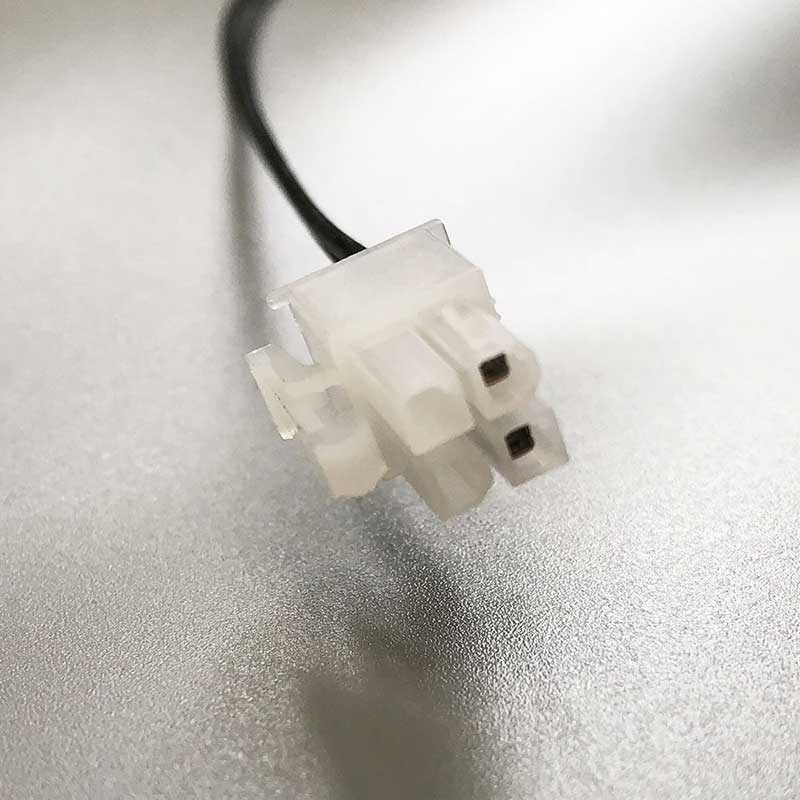

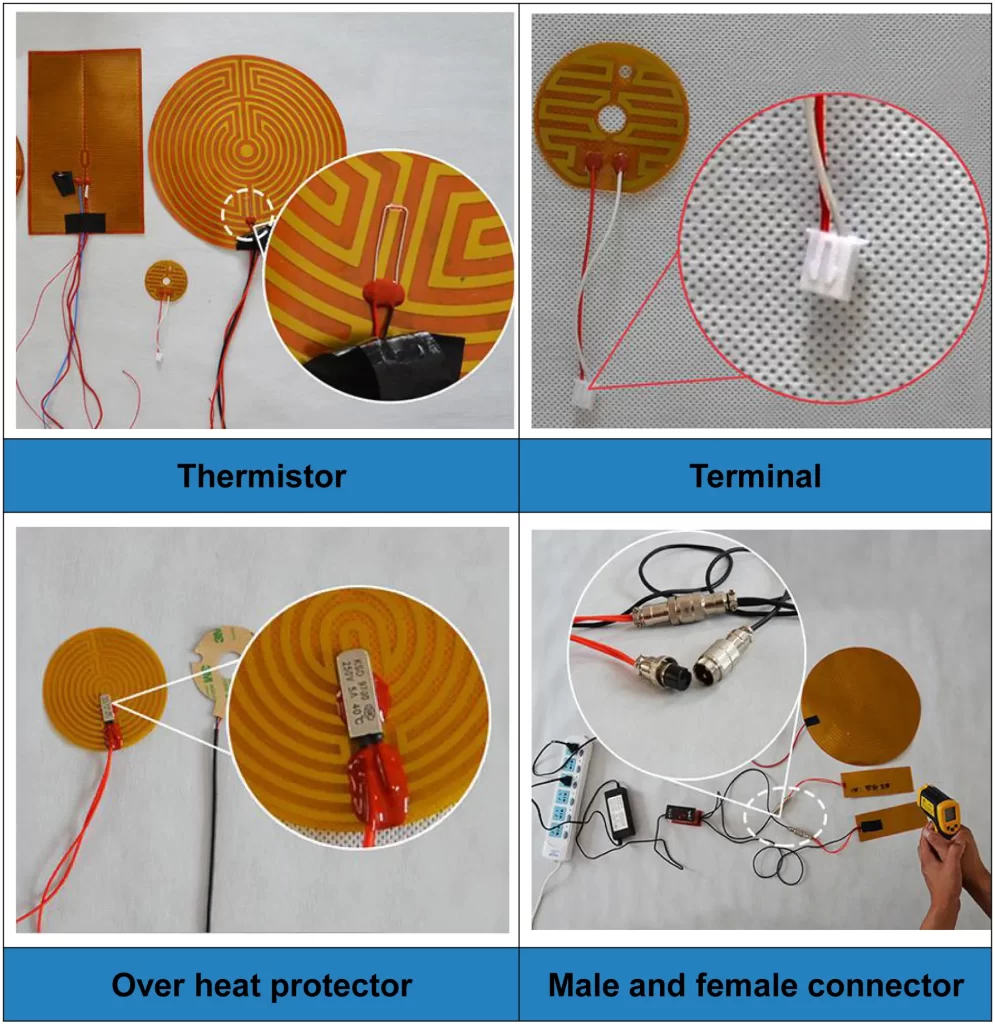

what are the connector types for PI/Poyimide heater?

- Solder pads: These are small, flat areas of the Polyimide film that have been treated with a special adhesive that allows them to be soldered to wires or other connectors.

- Flexible printed circuit (FPC) connectors: These are thin, flexible circuits that have been designed to be used as connectors for Polyimide heaters. FPC connectors are often used when a more robust, repeatable connection is required, as they are less prone to breaking or coming loose than soldered connections.

- Wire leads: These are simply wires that are attached to the Polyimide heater using solder or other methods. Wire leads are a simple and effective way to connect the heater to a power source, but they can be less reliable than other types of connectors.

- Quick-connect terminals: These are connectors that allow for easy and quick attachment of wires to the Polyimide heater. Quick-connect terminals can save time during assembly and may be a good choice for applications where the heater will need to be frequently connected and disconnected.

- Board-to-board connectors: These are connectors that allow for two circuit boards to be connected together, with the Polyimide heater acting as a bridge between them. Board-to-board connectors can be useful in applications where space is limited and multiple circuit boards need to be connected.

- Spring-loaded connectors: These are connectors that use a spring mechanism to establish a secure and reliable electrical connection with the Polyimide heater. Spring-loaded connectors can provide a high level of contact force and vibration resistance, making them a good choice for applications where the heater will be subjected to mechanical stress or vibration.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Polyimide Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–290℃

|

|

Cable conductor

|

Silicone insulated leads

|

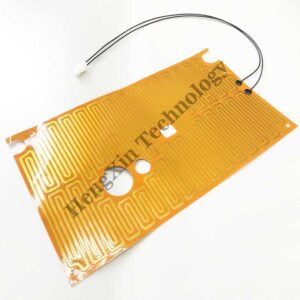

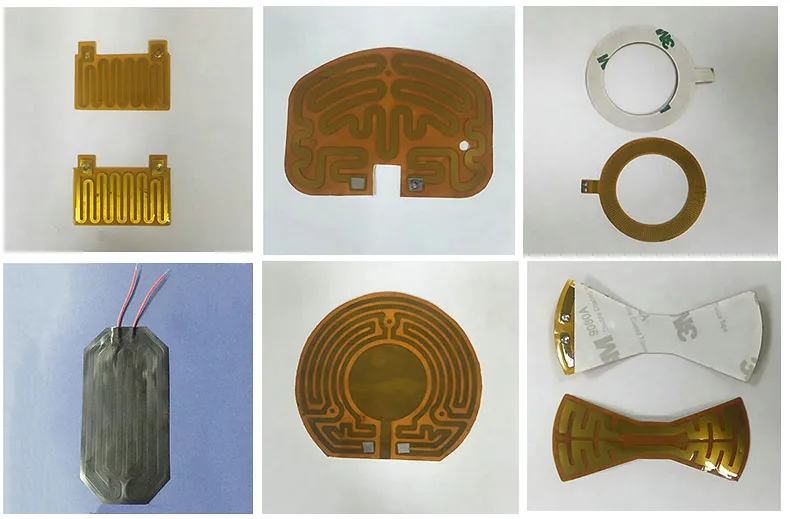

Configuration of the PI heater

PI heater in different shapes

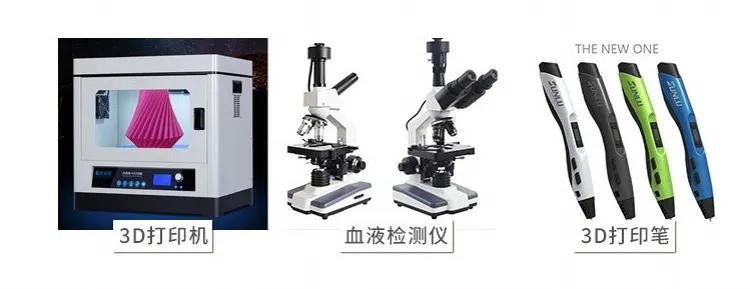

PI heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

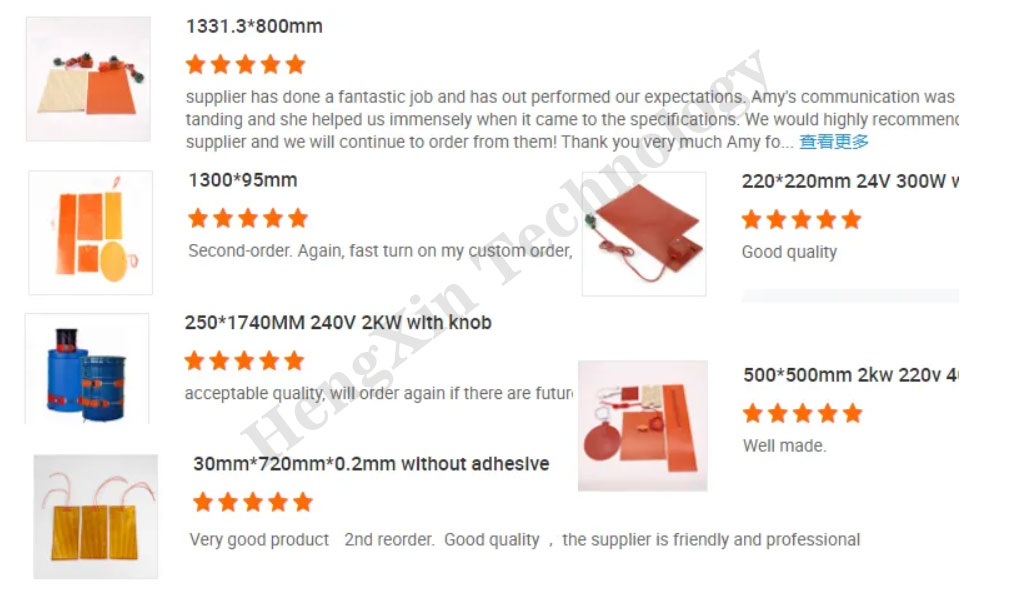

Customers Feedback for our products

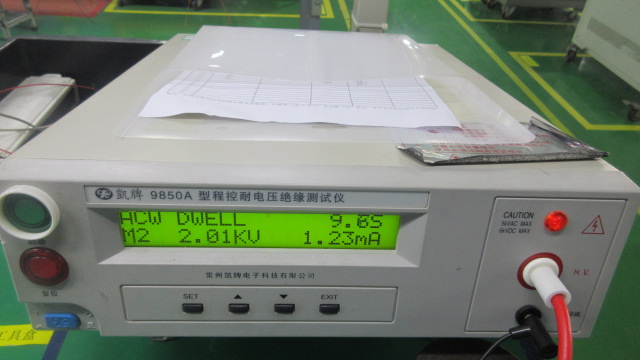

Certificates of the heating elements

Other products you may interest:

PI Heater is at the forefront of the heating industry, providing energy-efficient heating solutions for modern industries. Our heating solutions, including infrared heaters, radiant heaters, and heating elements, are designed with temperature control technology to ensure precision and accuracy. We understand the importance of energy efficiency, which is why we strive to create heating solutions that are eco-friendly and reduce energy consumption. With our innovative products and advanced technology, we’re revolutionizing the way industries heat their facilities. PI Heaters is dedicated to providing top-of-the-line heating solutions that are reliable, efficient, and effective. Join us and choose PI Heaters for all your heating needs,our warranty for the Pi heaters manufactured is 50,000 hours in normal working environment and we have different connector and temperature control for your option.

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]