Kapton heater for 3D printing pen description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 200 ℃

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

Kapton heater for 3D printing pen definition

A Kapton heater is a type of heating element commonly used in 3D printing pens. It is named after the material it is made from, which is Kapton, a polyimide film known for its excellent thermal stability and electrical insulation properties.

In the context of a 3D printing pen, the Kapton heater is responsible for heating up the thermoplastic filament as it passes through the pen, allowing it to melt and be extruded through the nozzle. The Kapton heater is typically wrapped around the nozzle or integrated into the pen’s design to provide controlled and even heating.

Kapton heaters are preferred in 3D printing pens because they can reach high temperatures quickly and maintain a consistent temperature during operation. The Kapton film used in the heater is thin and flexible, making it suitable for conforming to the shape of the pen and providing efficient heat transfer.

What is Kapton heater?

Kapton heater is a type of flexible heating element made from a thin, lightweight polyimide film called Kapton. Kapton heaters are designed to be highly efficient and reliable, and they can be custom-made to fit a variety of shapes and sizes. They are often used in a wide range of applications where uniform and efficient heating is required, such as in aerospace, medical, and electronics industries.

Kapton heaters are known for their excellent resistance to temperature extremes, chemicals, and radiation. They are also highly flexible, which makes them ideal for use in applications that require a conformable heating element that can be bent or shaped to fit specific contours. Additionally, Kapton heaters have a fast heat-up time and can achieve high temperatures quickly and evenly, making them ideal for applications where fast and precise heating is required.

How does Kapton heater for 3D printing pen work?

A Kapton heater for a 3D printing pen works by utilizing the electrical resistance of the Kapton film to generate heat. Here’s a step-by-step explanation of how it functions:

Electrical current: The Kapton heater is connected to an electrical power source, typically low voltage, through a set of wires. When the power is switched on, the current flows through the wires and into the Kapton heater.

Electrical resistance: Kapton is a polyimide film with specific electrical resistance. As the current passes through the Kapton film, it encounters resistance. According to Ohm’s law (V = I * R), where V is voltage, I is current, and R is resistance, this resistance causes a voltage drop across the Kapton film.

Heat generation: The voltage drop across the Kapton film leads to the conversion of electrical energy into heat energy. This process occurs due to the Joule heating effect, where the resistance of the Kapton film causes the electrons in the material to collide with atoms, generating heat as a byproduct.

Heat transfer: The heat generated by the Kapton heater is transferred to the surrounding components, particularly the nozzle or the area where the filament passes through. The Kapton film is designed to have good thermal conductivity, allowing the heat to efficiently transfer to the desired location.

Filament melting: As the nozzle or the area surrounding the filament receives heat from the Kapton heater, it reaches the desired temperature for melting the thermoplastic filament. The filament is fed into the heated area of the pen, where it softens and becomes malleable.

Extrusion: With the filament in a molten state, the user can control the flow of the material by manually pushing or pulling the filament through the pen. The melted filament is then extruded through the nozzle, allowing the user to create three-dimensional shapes or drawings.

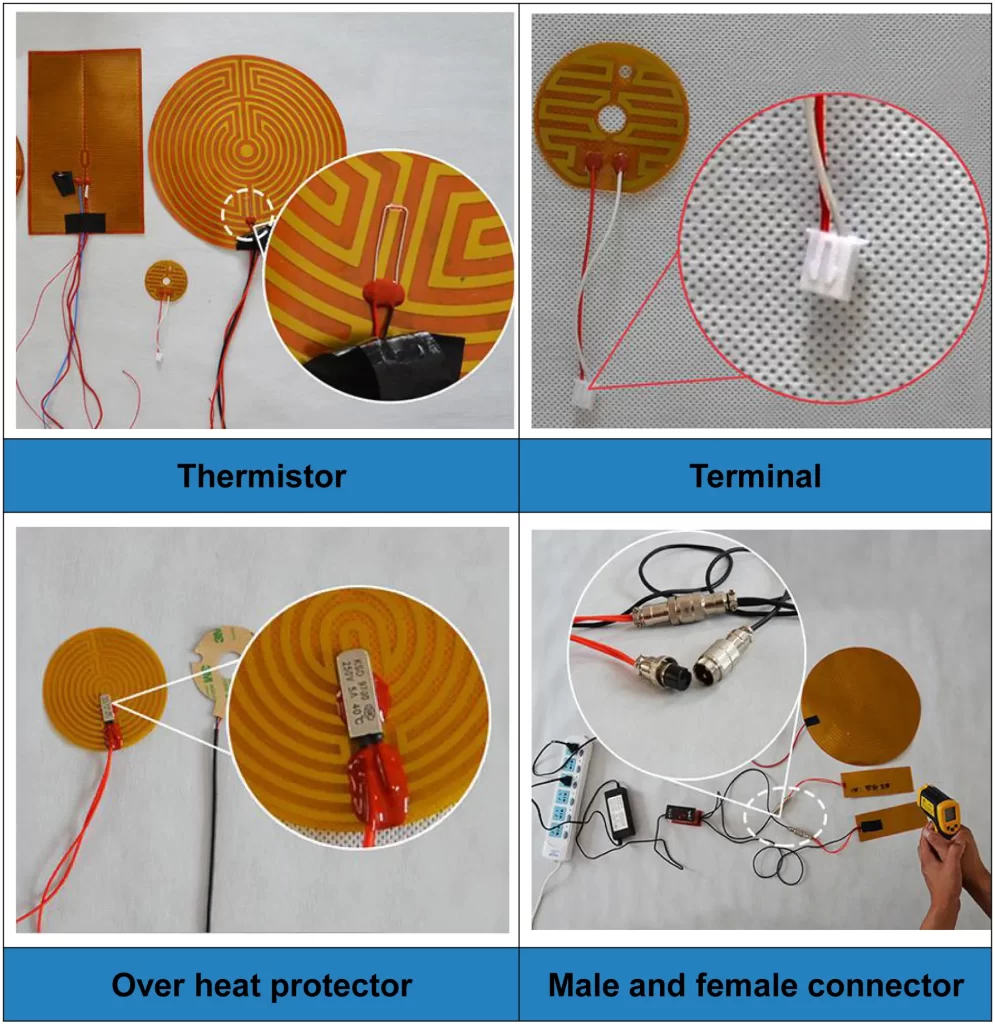

Temperature control: To ensure proper operation and prevent overheating, Kapton heaters for 3D printing pens often incorporate temperature control mechanisms. These mechanisms may include thermistors or other sensors that monitor the temperature and regulate the power supplied to the Kapton heater accordingly, maintaining a consistent and safe temperature.

.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–290℃

|

|

Cable conductor

|

Silicone insulated leads

|

Configuration of the Kapton heater

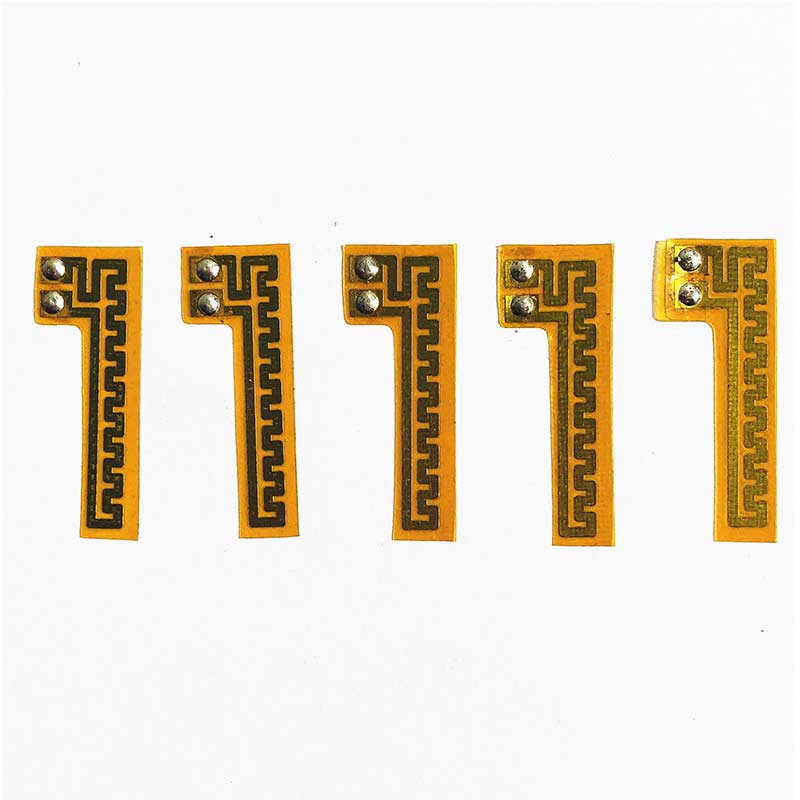

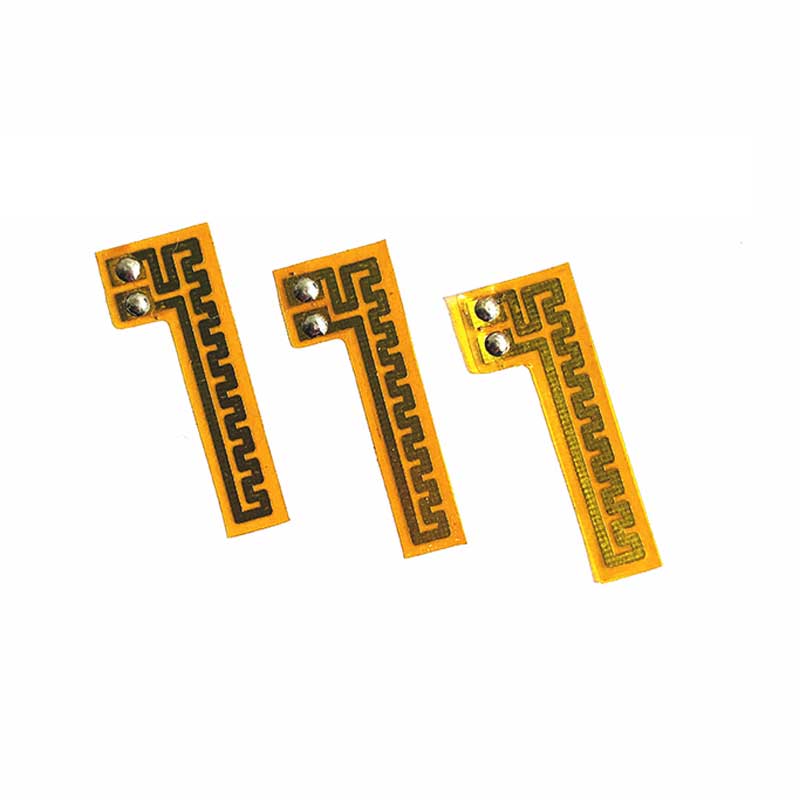

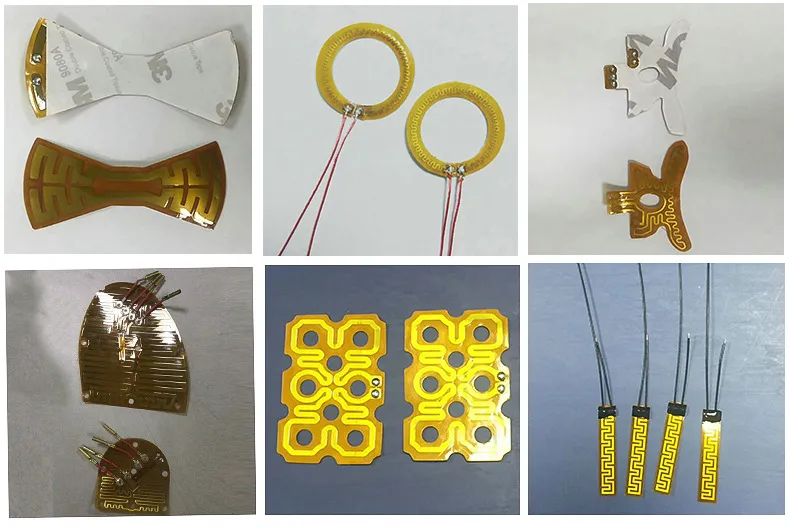

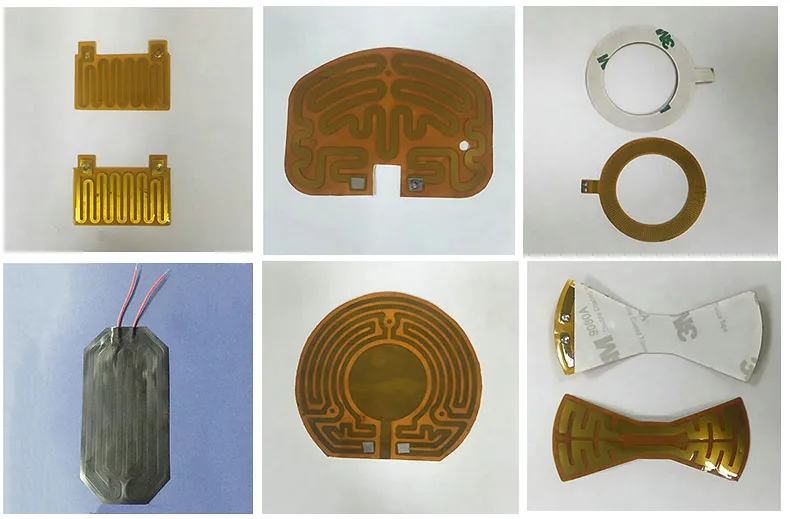

Kapton heater in different shapes

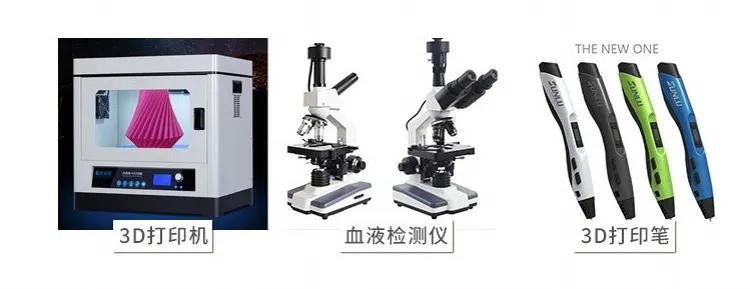

Kapton heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

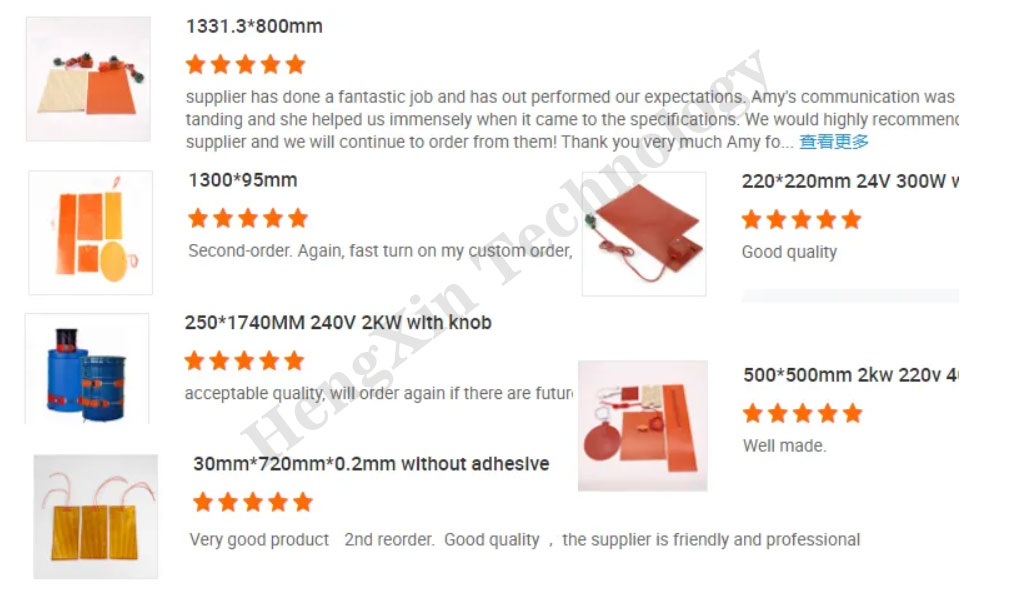

Customers Feedback for our products

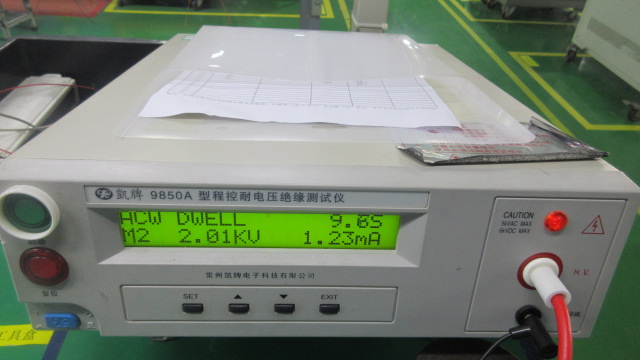

Certificates of the heating elements

Other products you may interest:

Kapton Heater leads the heating industry by offering energy-efficient heating solutions for modern industries. Our heating solutions, which include infrared heaters, radiant heaters, and heating elements, incorporate temperature control technology for precise and accurate heating. Our commitment to energy efficiency is evident in our eco-friendly heating solutions that minimize energy consumption. Our cutting-edge products and advanced technology are revolutionizing industrial heating. At Kapton Heaters, we are dedicated to delivering reliable, efficient, and effective heating solutions. Trust us for all your heating needs. Our Kapton heaters are backed by a 50,000-hour warranty in normal working conditions, and we offer various connector and temperature control options to suit your preferences.

Our team at Kapton Heater is composed of highly skilled and experienced professionals who are passionate about providing excellent customer service. We work closely with our clients to understand their unique heating needs and develop customized solutions that meet their requirements. Whether you’re looking to heat a small laboratory or a large industrial facility, we have the expertise and resources to deliver optimal heating solutions.

At Kapton Heater, we prioritize safety and compliance with industry standards. Our heating solutions are manufactured using high-quality materials and adhere to rigorous safety protocols to ensure safe and reliable operation. We also offer installation and maintenance services to ensure that your heating solutions are operating at their best.

Choose Kapton Heater for all your heating needs and experience the benefits of our energy-efficient, eco-friendly, and reliable heating solutions.

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]