What is Kapton Heater?

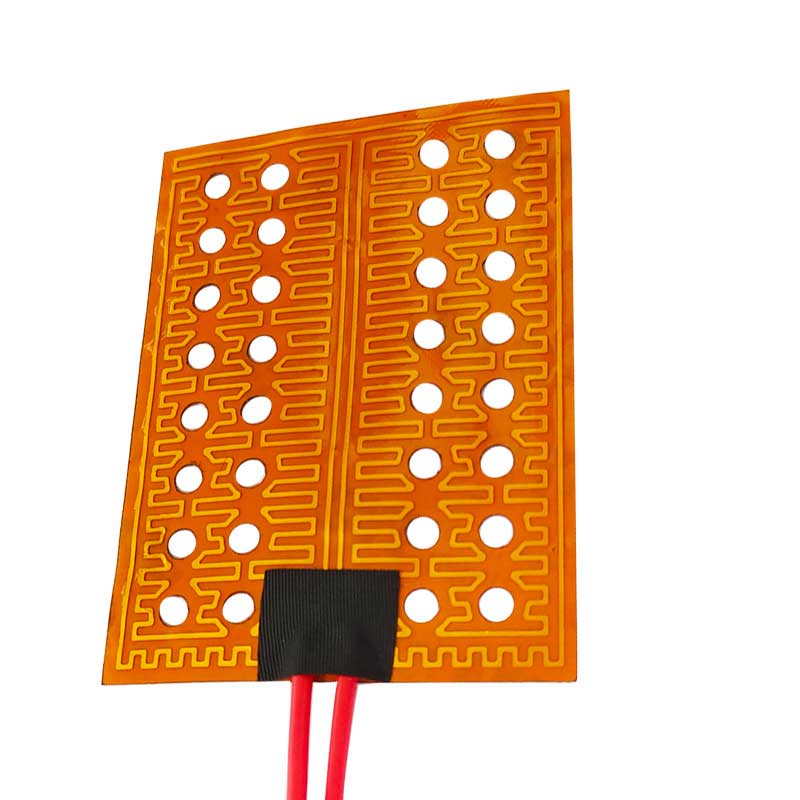

A Kapton heater is a type of flexible and thin heating element that is made from a polyimide film called Kapton. Kapton is a high-temperature resistant polymer that can withstand temperatures up to 400°C (752°F) and is commonly used in high-temperature applications.

Kapton heaters are designed to provide a uniform and controlled heat source in a variety of industries such as aerospace, automotive, medical, and electronics. They are typically used in applications where traditional heating elements cannot be used due to size or shape constraints, or where a high degree of flexibility is required.

Kapton heaters are lightweight, flexible, and have excellent thermal conductivity, making them ideal for use in applications where rapid heat transfer is required. They are also resistant to moisture, chemicals, and radiation, making them suitable for use in harsh environments.

What are the application for Kapton Heater?

Aerospace and aviation: Kapton heaters are used in aircraft engines, wings, and avionics systems to prevent fuel from freezing and to maintain optimal temperatures.

Medical equipment: Kapton heaters are used in medical devices such as blood analyzers, fluid warmers, and laboratory equipment that require precise and controlled heating.

Food processing equipment: Kapton heaters are used in food processing equipment such as ovens, grills, and cookers to provide uniform heating and temperature control.

Semiconductor manufacturing: Kapton heaters are used in the production of semiconductor chips to maintain precise temperatures during the manufacturing process.

Automotive industry: Kapton heaters are used in automotive applications such as seat warmers, defrosting systems, and engine preheating systems.

3D printing: Kapton heaters are used in 3D printers to maintain consistent temperatures and prevent warping of the printing material.

What are the parameters for Kapton Heater?

The parameters for Kapton heaters depend on the specific application and requirements, but some common parameters include:

Wattage: The wattage of a Kapton heater refers to the amount of power that the heater can produce. This is typically specified in watts per square inch (W/in²) or watts per square centimeter (W/cm²), and is based on the desired temperature and heating time for the application.

Voltage: The voltage required for a Kapton heater depends on the wattage and the resistance of the heater. Most Kapton heaters operate at low voltages, typically between 12 and 120 volts.

Size and shape: Kapton heaters can be customized to fit a wide range of sizes and shapes, including round, square, and rectangular shapes. The size and shape of the heater are determined by the specific application requirements.

Temperature range: Kapton heaters can operate at a wide range of temperatures, typically up to 400°C (752°F). The temperature range required for a specific application depends on the materials being heated and the desired temperature profile.

Heating time: The heating time required for a Kapton heater depends on the wattage and the size of the heater, as well as the materials being heated and the desired temperature profile. The heating time is typically specified in seconds or minutes.

Resistance: The resistance of a Kapton heater determines the amount of current required to produce the desired wattage. The resistance is typically specified in ohms and is based on the desired wattage and voltage for the application.

What’s the production procedure of the Kapton Heater?

The production procedure of Kapton heaters typically involves the following steps:

Design and customization: The first step is to design and customize the Kapton heater based on the specific requirements of the application. This includes determining the size and shape of the heater, the desired temperature profile, the wattage and voltage requirements, and any other specifications.

Material preparation: The next step is to prepare the Kapton material, which is typically a polyimide film. The Kapton film is cleaned and treated with a special adhesive that allows it to adhere to the heating element.

Etching or cutting: The Kapton film is then etched or cut using a precision laser or chemical etching process to create the desired pattern for the heating element. This can include a variety of shapes and sizes, depending on the specific application.

Heating element application: The etched Kapton film is then laminated onto the heating element, which is typically made from a thin sheet of metal or a flexible substrate. The heating element is then coated with a layer of insulation to prevent electrical shorts and to provide thermal insulation.

Wiring and connections: The next step is to wire and connect the heating element to a power source. This typically involves attaching lead wires to the heating element and insulating the connections to prevent electrical shorts.

Quality control: Once the Kapton heater is assembled, it undergoes rigorous quality control testing to ensure that it meets the required specifications and standards for the application.

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,Pet heater and Silicone heater with customized size and shape, with qualifed products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. 50000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

Contact Us now for any query please.

[ez-toc]