Customized Polyimide Heaters for Research description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 180 ℃

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is PI heater?

A PI film heater refers to a heating element that utilizes a Polyimide (PI) film as its base material. Polyimide is a versatile polymer known for its high-temperature resistance, excellent electrical insulation properties, and flexibility. PI film heaters are commonly used in various applications, including electronics, aerospace, automotive, and medical industries.

The PI film heater consists of a thin film of Polyimide with integrated heating elements. These heating elements are typically made of conductive materials like etched foil or printed resistive traces. The Polyimide film provides electrical insulation and mechanical support for the heating elements.

PI film heaters are flexible and can conform to various shapes and surfaces, making them suitable for applications where space is limited or a custom fit is required. They offer uniform heat distribution and rapid heating capabilities.

How does PI Heater Work?

A PI heater, or a Polyimide film heater, works based on the principle of resistive heating. The Polyimide film, which serves as the base material, contains integrated heating elements made of conductive materials.

When an electric current is passed through the heating elements, they resist the flow of electricity, causing them to heat up. This heat is then transferred to the surrounding environment or the object in contact with the PI heater.

The Polyimide film in the heater acts as an insulator, preventing electrical current from directly contacting the object being heated. It also provides mechanical support and flexibility to the heater, allowing it to conform to various shapes and surfaces.

The resistance of the heating elements determines the amount of heat generated. By controlling the electrical current flowing through the heater, the temperature output can be adjusted to achieve the desired level of heating.

What is Customized Polyimide Heaters for Research?

Customized polyimide heaters offer a versatile solution for research applications across various fields. Their flexibility, thin profile, and excellent thermal stability make them ideal for environments where traditional heaters are impractical. Whether you’re conducting experiments in aerospace, electronics, biotechnology, or materials science, these heaters can provide precise and uniform heating, crucial for maintaining experimental conditions. Their customizable nature allows for tailored designs to fit specific research setups, ensuring optimal performance and efficiency. With polyimide heaters, researchers can advance their investigations with confidence, knowing they have a reliable heating solution adaptable to their unique requirements.

Polyimide heaters are constructed using high-quality materials that offer durability and resistance to harsh operating conditions, including chemical exposure and mechanical stress. This resilience makes them suitable for long-term use in research settings where reliability is paramount.

Furthermore, the flexibility of polyimide heaters enables them to conform to various shapes and contours, allowing for integration into complex experimental setups or devices with irregular geometries. This adaptability facilitates seamless incorporation into research projects, minimizing design constraints and maximizing efficiency.

In addition to their physical properties, polyimide heaters can be customized in terms of wattage, voltage, size, and shape to meet specific heating requirements. This customization capability ensures that researchers can achieve precise temperature control and uniform heating distribution tailored to their experimental needs.

Moreover, polyimide heaters offer rapid heating and cooling cycles, contributing to efficient experimentation and data collection. Their low thermal mass allows for quick response times, enabling researchers to adjust temperatures promptly and maintain precise thermal conditions throughout their studies.

Polyimide heaters offer several additional advantages for research applications:

Temperature Uniformity: Polyimide heaters provide consistent heating across their surface, ensuring uniform temperature distribution. This uniformity is essential for maintaining the integrity and reliability of experimental results, especially in studies where temperature-sensitive materials or processes are involved.

Low Outgassing: Polyimide materials exhibit minimal outgassing, making them suitable for use in vacuum or cleanroom environments common in research settings. This characteristic prevents contamination of experimental setups and ensures the purity of research samples.

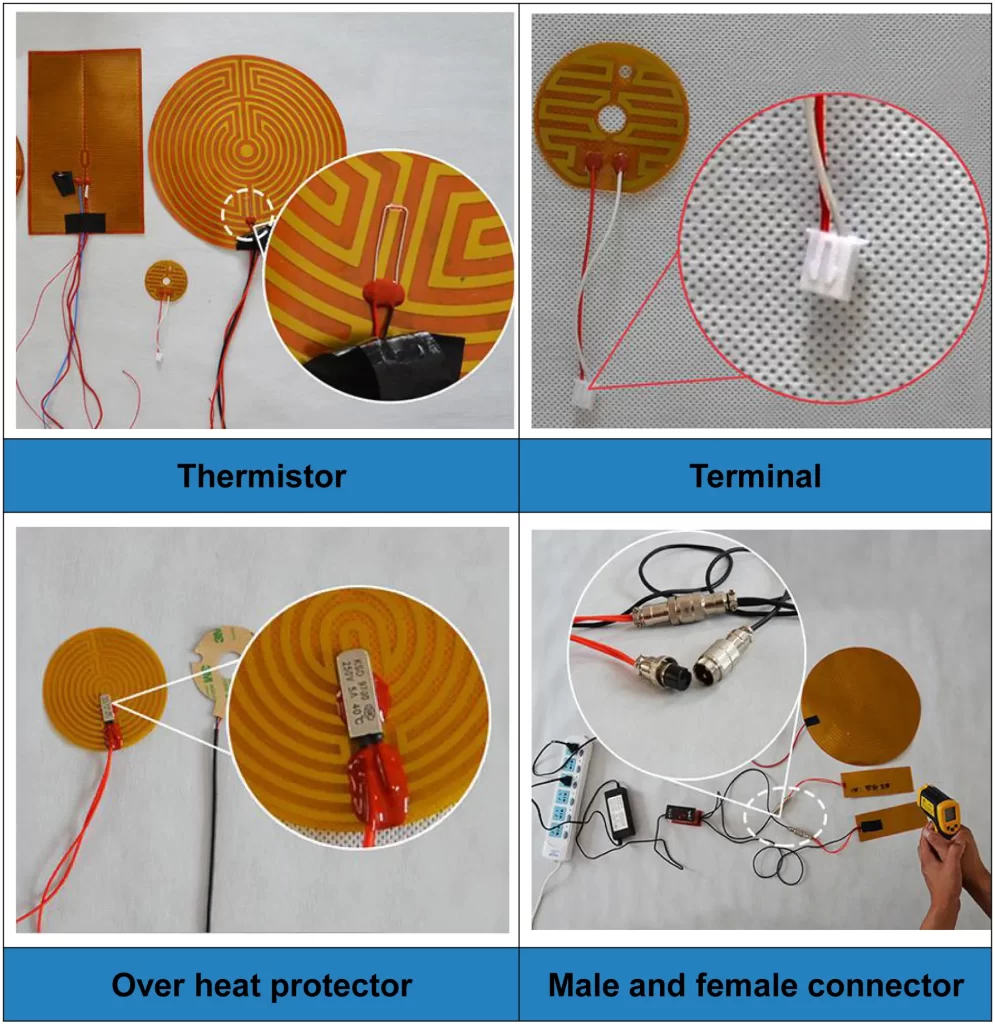

Versatile Attachment Methods: Polyimide heaters can be easily integrated into research equipment using various attachment methods, such as adhesive backing, clamps, or custom fixtures. This versatility simplifies installation and allows researchers to adapt the heaters to different experimental configurations without extensive modifications.

Customizable Sensor Integration: Polyimide heaters can be designed with built-in temperature sensors or accommodate external sensors for precise temperature monitoring and control. This capability enables researchers to maintain tight control over experimental conditions and accurately record temperature data for analysis.

Energy Efficiency: Polyimide heaters are energy-efficient, consuming minimal power to achieve and maintain desired temperatures. This efficiency not only reduces operational costs but also minimizes the impact of heat generation on surrounding environments or sensitive research materials.

Safety Features: Polyimide heaters are inherently safe to use, with low risk of electrical hazards or thermal runaway. Additionally, they can be engineered with built-in safety mechanisms, such as temperature limiters or insulation barriers, to prevent overheating and ensure researcher safety during prolonged experiments.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–180℃

|

|

Cable conductor

|

Silicone insulated leads

|

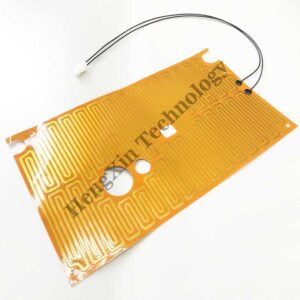

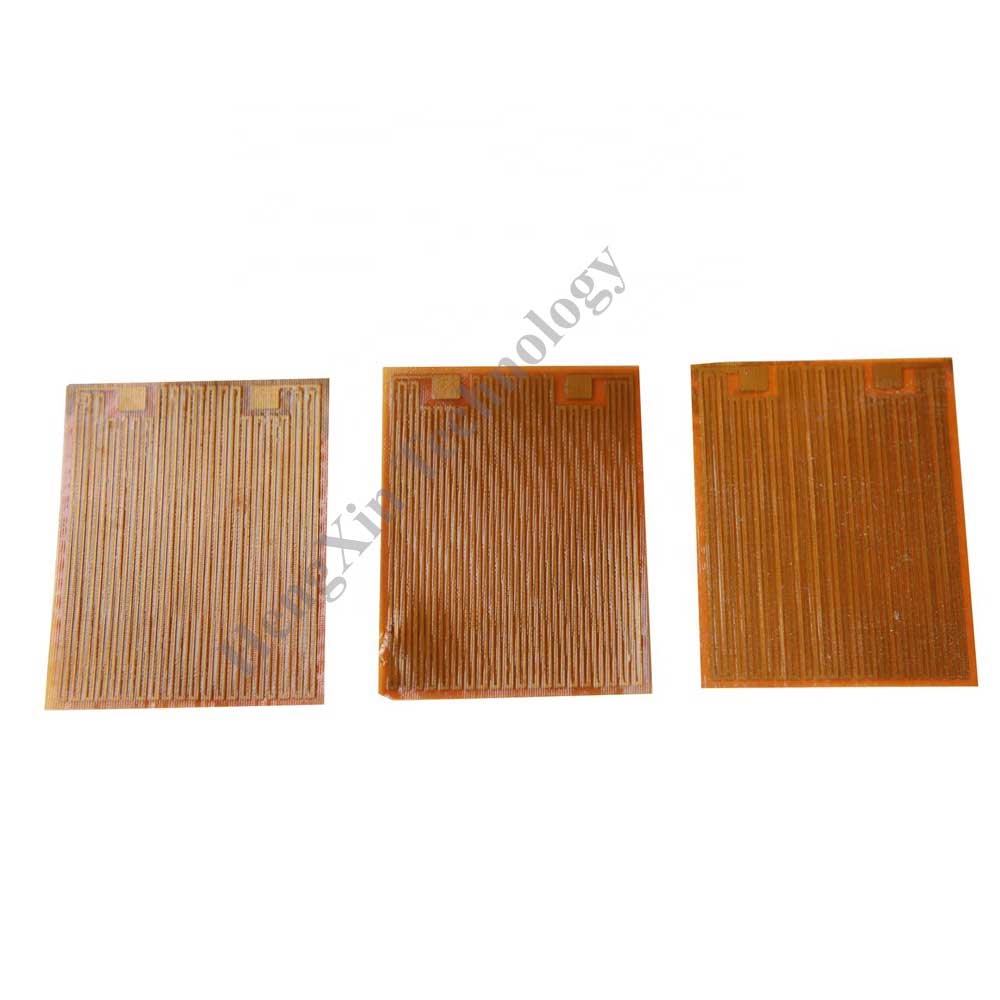

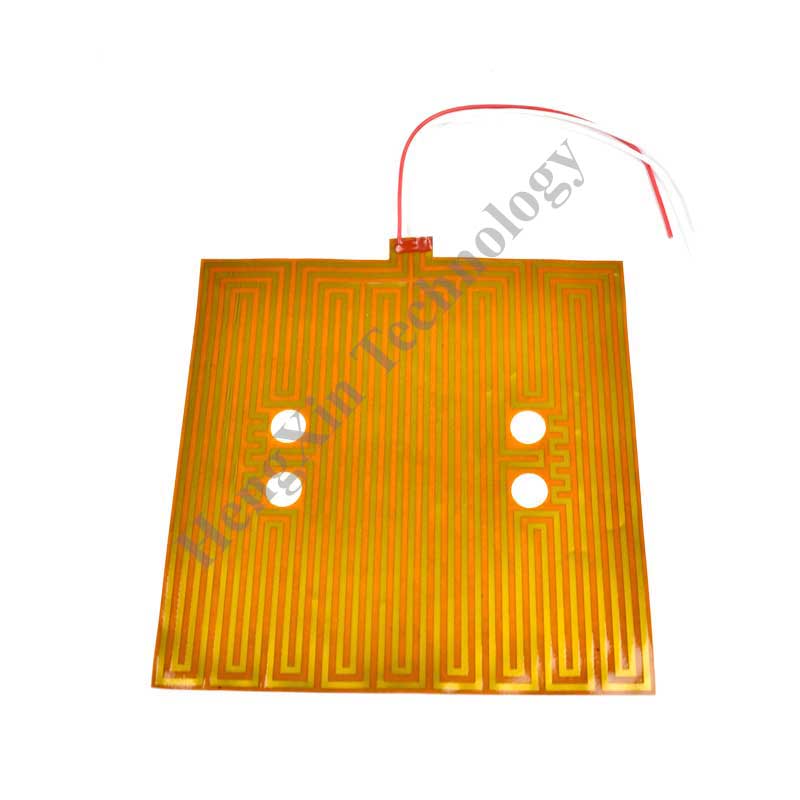

Configuration of the PI heater

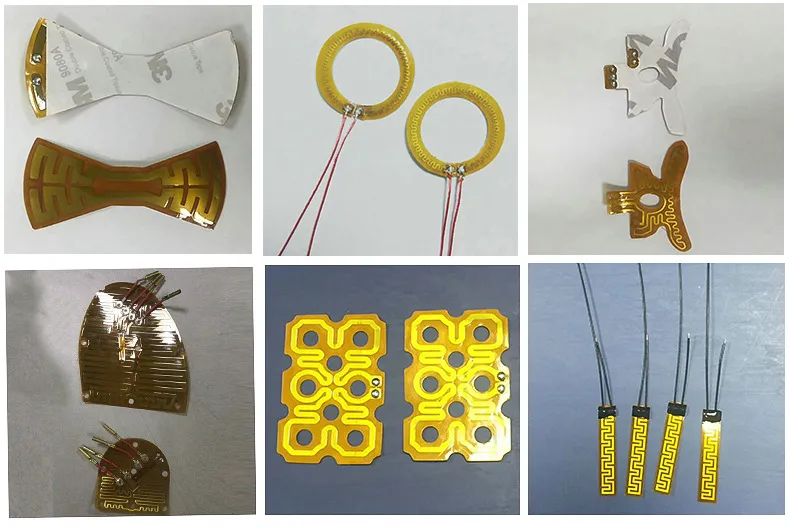

PI heaters in different shapes

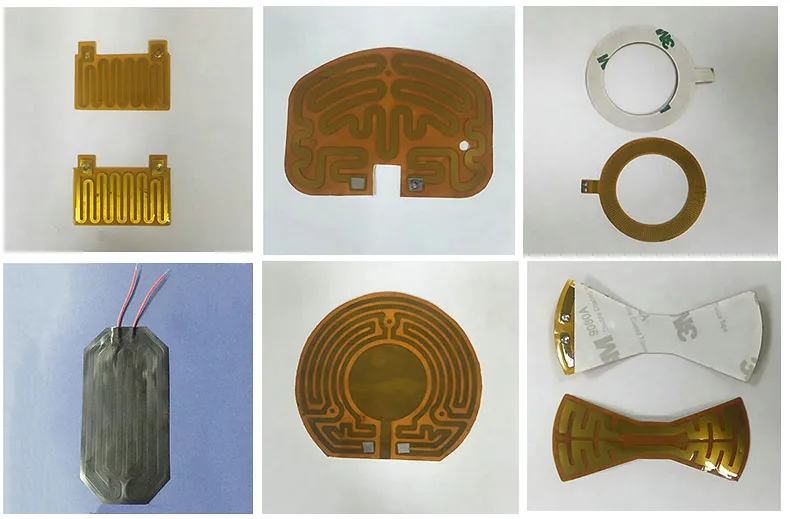

Pi heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

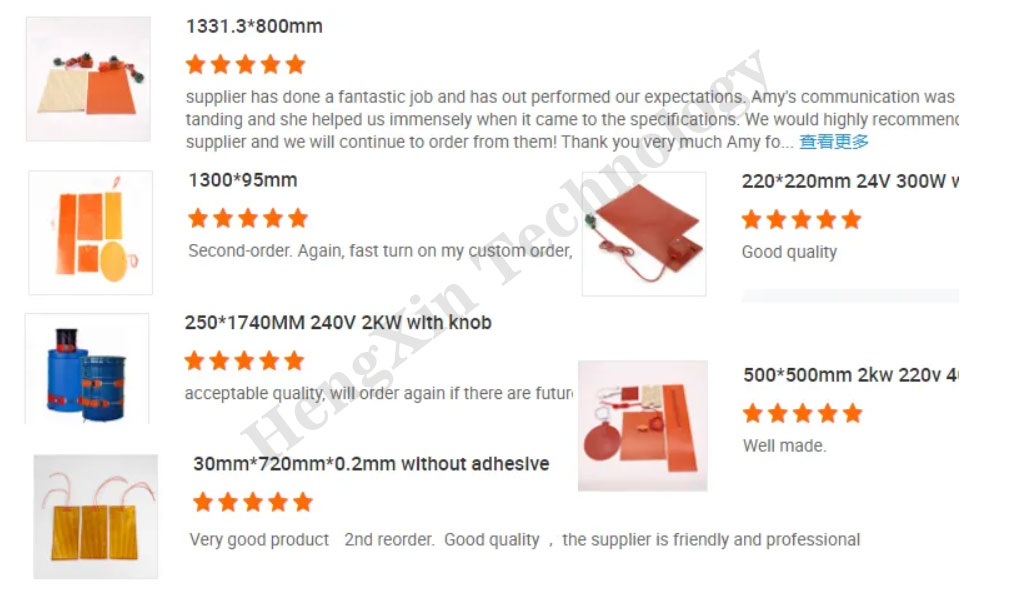

Customers Feedback for our products

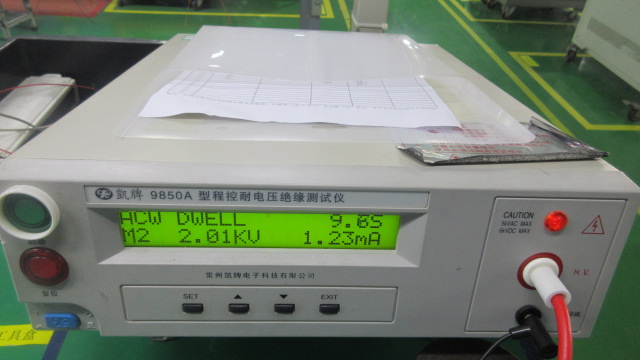

Certificates of the heating elements

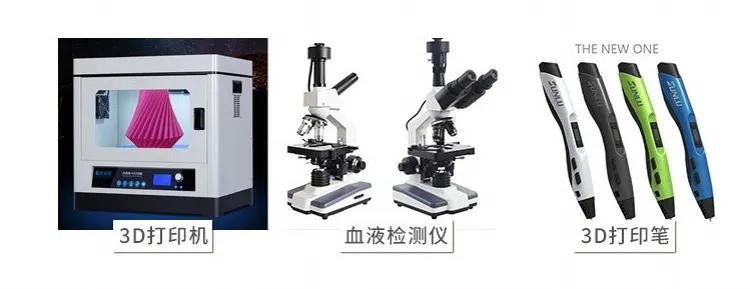

Other products you may interest:

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]