Kapton heater for new energy vehicle lithium battery description

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 200 ℃

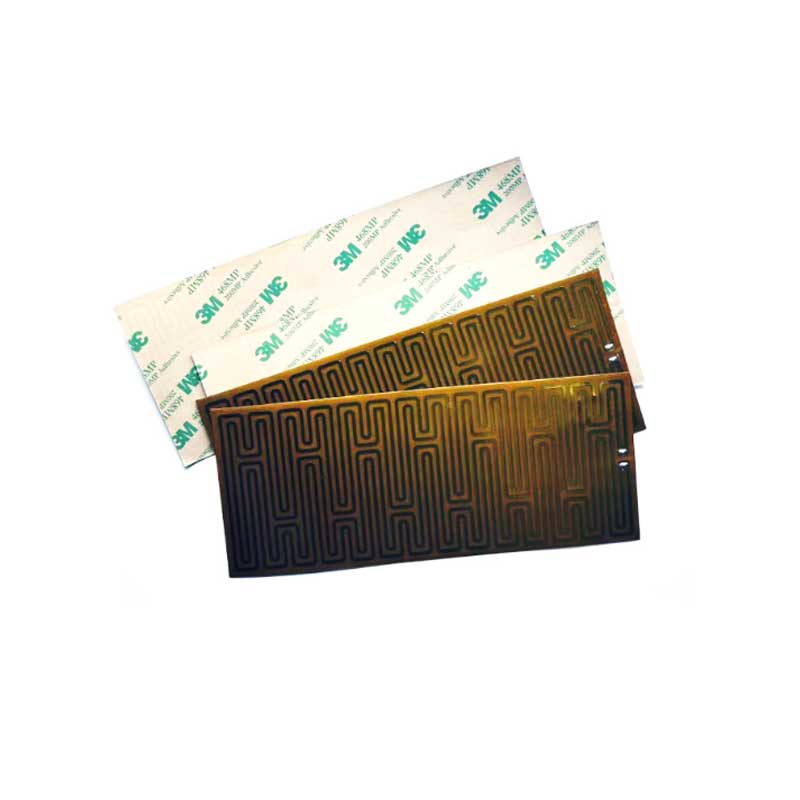

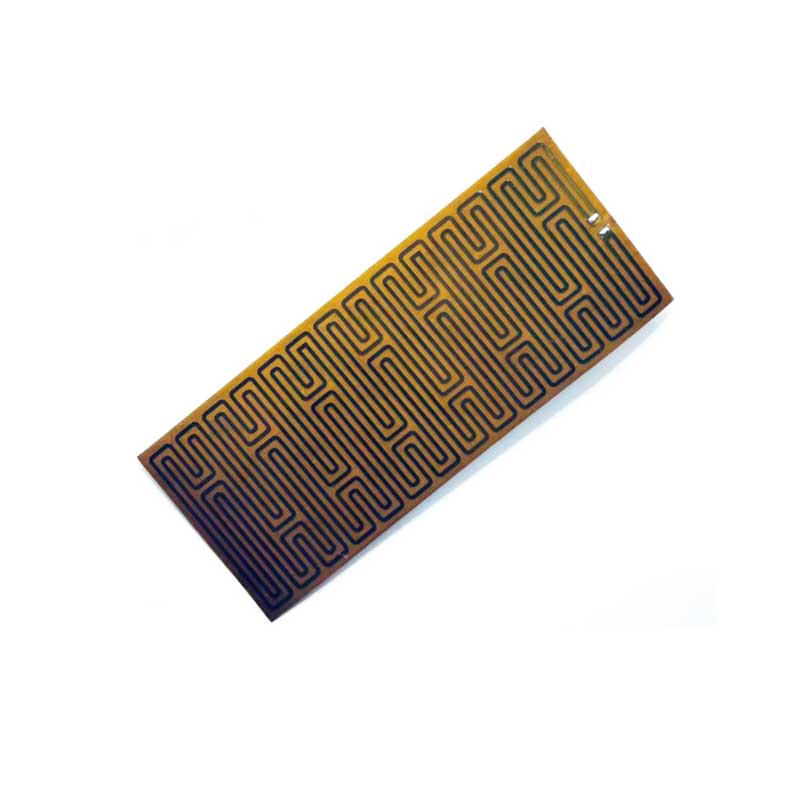

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

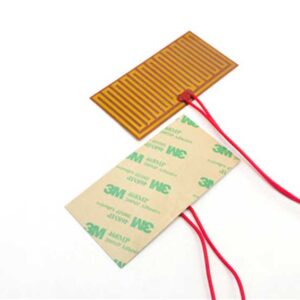

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is Kapton heater for new energy vehicle lithium battery

A Kapton heater, also known as a Kapton flexible heater or Kapton polyimide heater, is a type of flexible heating element used in various applications, including new energy vehicle (NEV) lithium battery systems. Kapton is a brand name for a polyimide film developed by DuPont, and it has excellent thermal and electrical properties, making it ideal for creating flexible heaters.

In NEV lithium battery applications, Kapton heaters are often used for battery heating and temperature management. Lithium-ion batteries perform optimally within a specific temperature range, typically between 20°C to 35°C (68°F to 95°F). Below this range, the battery may have reduced performance and capacity, while above this range, it can experience decreased lifespan and potential safety risks, like thermal runaway.

Kapton heaters are designed to provide uniform and consistent heat distribution, ensuring that the lithium-ion batteries are kept within the desired temperature range, especially in colder climates or during extreme weather conditions. These heaters are thin, lightweight, and can be custom-made to fit the specific size and shape of the battery pack or individual battery cells.

The benefits of using Kapton heaters for NEV lithium battery applications include:

Flexibility: Kapton heaters are flexible and conformable, which means they can be applied directly to the battery surface or wrapped around individual cells or modules without adding much bulk or weight to the battery pack.

Rapid Heat Transfer: Kapton heaters have good thermal conductivity, allowing them to quickly transfer heat to the battery, helping to maintain the desired operating temperature.

Even Distribution of Heat: The uniform heat distribution of Kapton heaters prevents localized hotspots within the battery pack, which can be crucial for maintaining the battery’s health and safety.

Resistance to Chemicals: Kapton is highly resistant to various chemicals, including those found in the battery environment, which helps ensure the heater’s long-term performance and reliability.

Temperature Control: Kapton heaters can be engineered to provide precise temperature control, either through simple thermostats or more advanced control systems, depending on the battery’s requirements

How does Kapton heater for new energy vehicle lithium battery work?

The Kapton heater for a new energy vehicle (NEV) lithium battery works on the principle of resistive heating. It is essentially a flexible resistive heating element made using a Kapton polyimide film as the substrate. Here’s how it operates:

Construction: The Kapton heater consists of a thin layer of Kapton polyimide film, which serves as the flexible base material. Onto this film, a resistive heating element is deposited or etched using conductive materials, such as a thin layer of conductive ink or metal traces.

Electrical Current: When an electrical current is passed through the resistive heating element, it encounters resistance, as per Ohm’s law (V=IR), where V is voltage, I is current, and R is resistance. This resistance generates heat as a byproduct.

Heat Generation: The resistive heating element is designed with a specific resistance per unit length, and the amount of current passing through it is regulated to control the amount of heat produced. The heater’s design ensures uniform heat distribution across its surface.

Temperature Control: To maintain the battery at the desired operating temperature, the Kapton heater can be equipped with a temperature control system. This control system could be as simple as a thermostat that turns the heater on or off based on the measured temperature. More sophisticated systems might utilize feedback loops with sensors and microcontrollers to precisely regulate the temperature within a narrow range.

Application: The Kapton heater is then applied to the battery pack or individual battery cells. Its flexibility allows it to conform to the battery’s shape and be attached securely using adhesives or other suitable methods. By placing the heater strategically, it ensures even heating throughout the battery pack.

Battery Heating: When the NEV is operating in cold weather or low-temperature conditions, the temperature control system activates the Kapton heater to generate heat. This heat is transferred to the lithium-ion battery, helping to keep it within the optimal operating temperature range.

Safety: The Kapton heater plays a crucial role in preventing the battery from getting too cold, as operating below the recommended temperature range can negatively affect battery performance and reduce its capacity. Additionally, keeping the battery within the desired temperature range helps avoid potential safety risks like thermal runaway or decreased efficiency.

In summary, the Kapton heater for NEV lithium batteries works by converting electrical energy into heat through resistive heating. Its flexibility, uniform heat distribution, and precise temperature control make it an essential component for ensuring the optimal performance, efficiency, and safety of lithium-ion batteries in new energy vehicles.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Kapton Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–290℃

|

|

Cable conductor

|

Silicone insulated leads

|

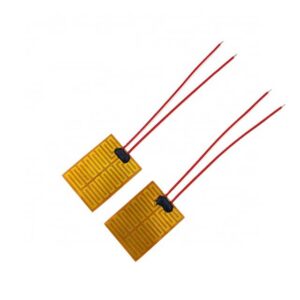

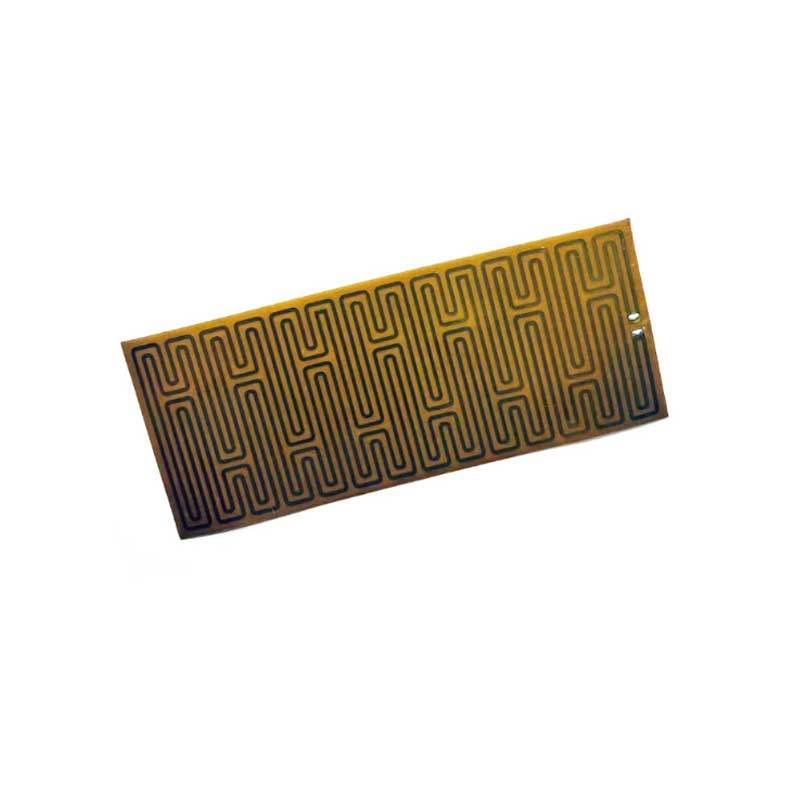

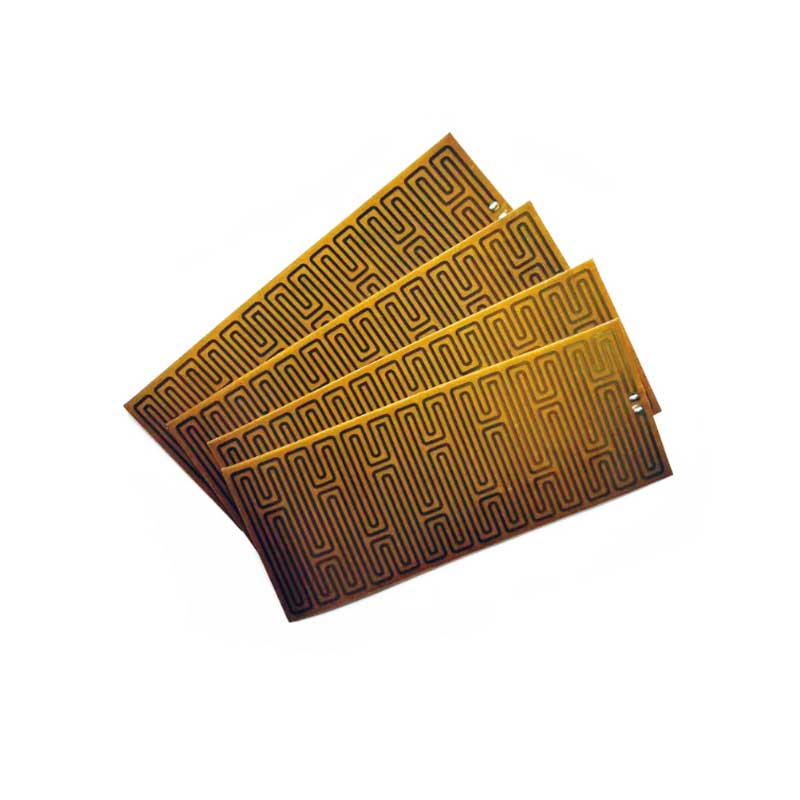

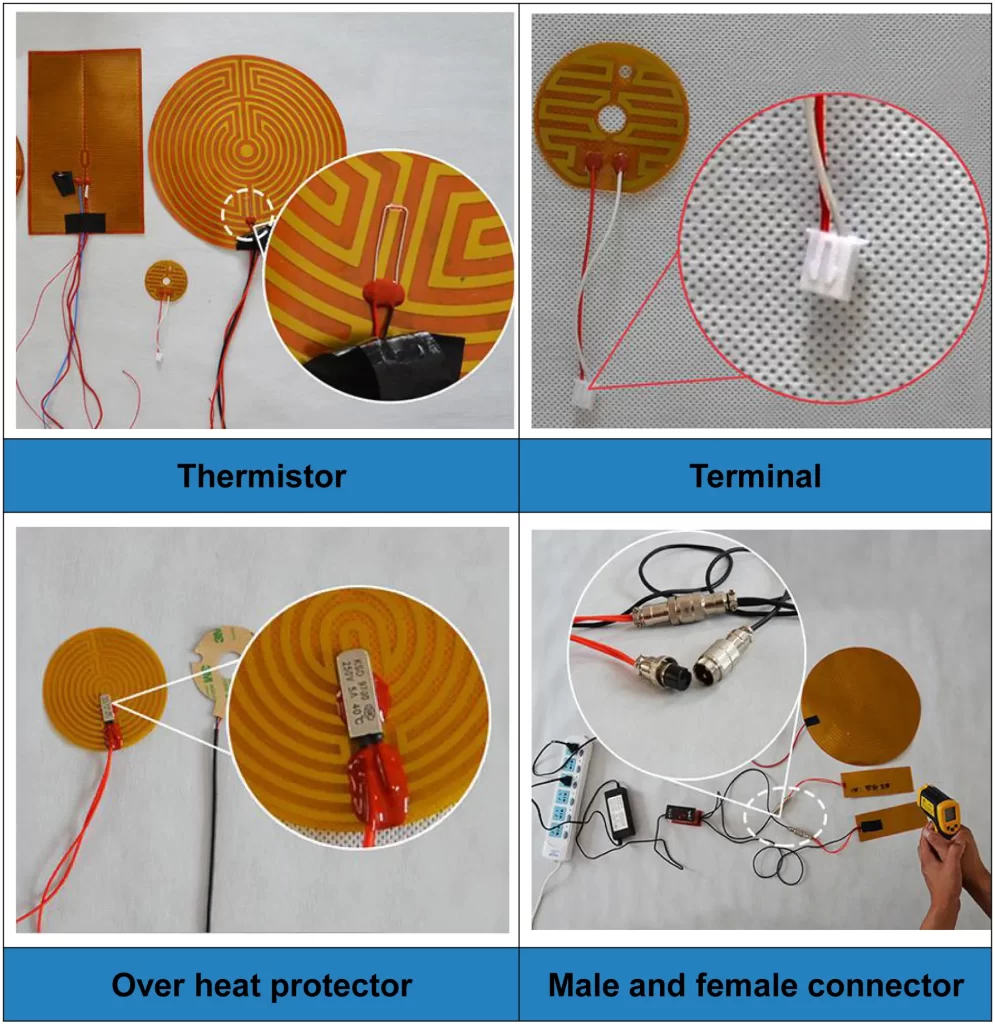

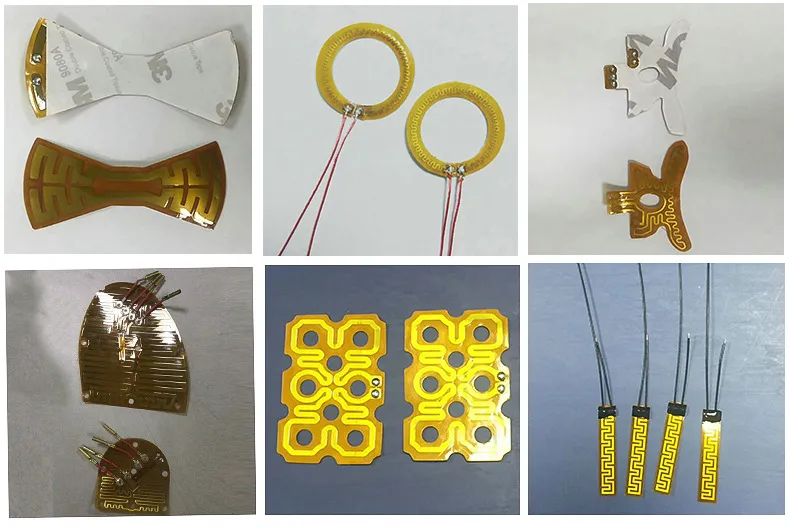

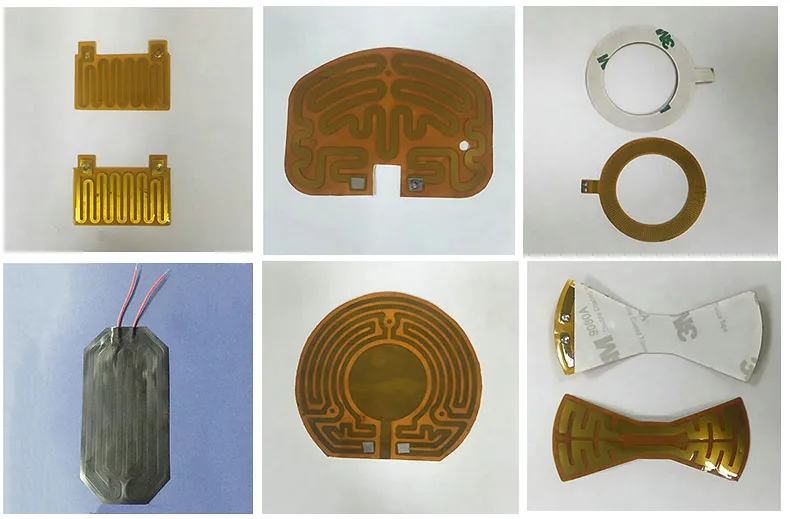

Configuration of the Kapton heater

Kapton heater in different shapes

Kapton heater Application

Our Factory

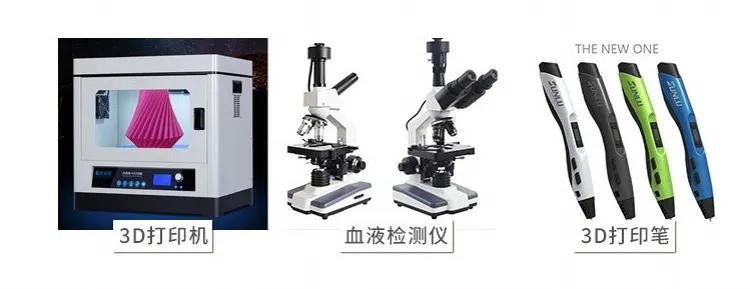

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

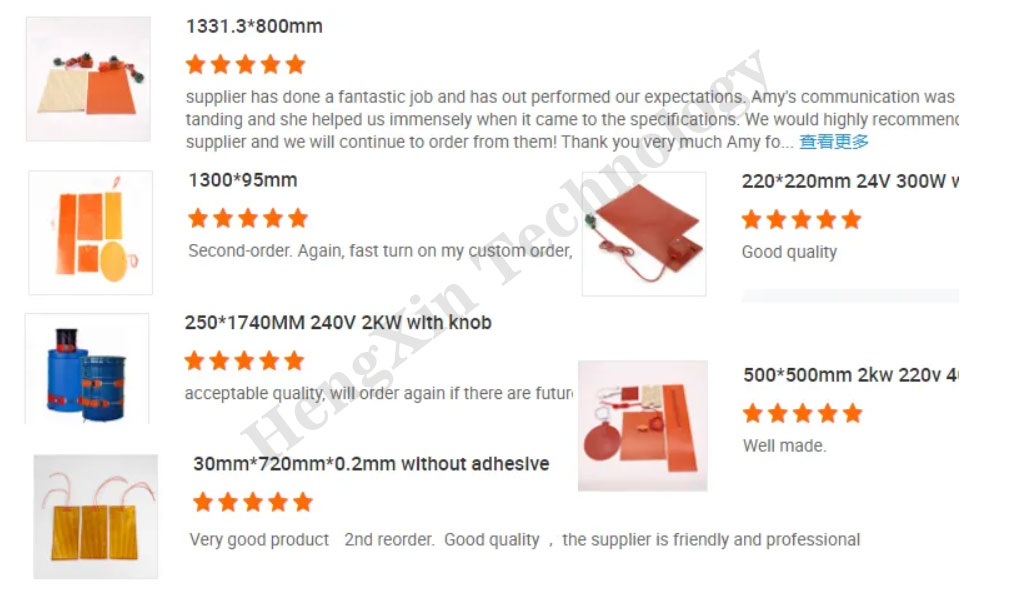

Customers Feedback for our products

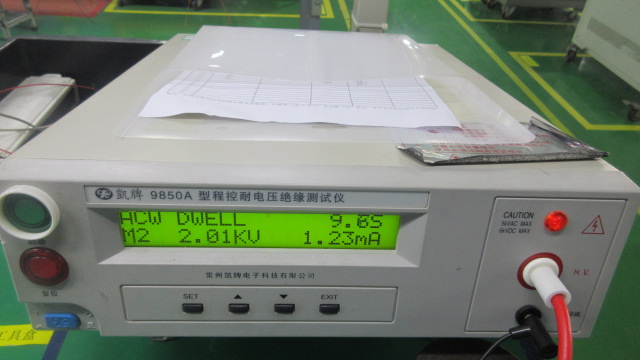

Certificates of the heating elements

Other products you may interest:

Kapton Heater leads the heating industry by offering energy-efficient heating solutions for modern industries. Our heating solutions, which include infrared heaters, radiant heaters, and heating elements, incorporate temperature control technology for precise and accurate heating. Our commitment to energy efficiency is evident in our eco-friendly heating solutions that minimize energy consumption. Our cutting-edge products and advanced technology are revolutionizing industrial heating. At Kapton Heaters, we are dedicated to delivering reliable, efficient, and effective heating solutions. Trust us for all your heating needs. Our Kapton heaters are backed by a 50,000-hour warranty in normal working conditions, and we offer various connector and temperature control options to suit your preferences.

Our team at Kapton Heater is composed of highly skilled and experienced professionals who are passionate about providing excellent customer service. We work closely with our clients to understand their unique heating needs and develop customized solutions that meet their requirements. Whether you’re looking to heat a small laboratory or a large industrial facility, we have the expertise and resources to deliver optimal heating solutions.

At Kapton Heater, we prioritize safety and compliance with industry standards. Our heating solutions are manufactured using high-quality materials and adhere to rigorous safety protocols to ensure safe and reliable operation. We also offer installation and maintenance services to ensure that your heating solutions are operating at their best.

Choose Kapton Heater for all your heating needs and experience the benefits of our energy-efficient, eco-friendly, and reliable heating solutions.

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.

[ez-toc]