12V industrial Pi heater description

Applicable Industries:Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other

Condition:New

Type:Electric Heater

Power Source:Electric

Place of Origin:Guangdong, China

Brand Name:Hengxin

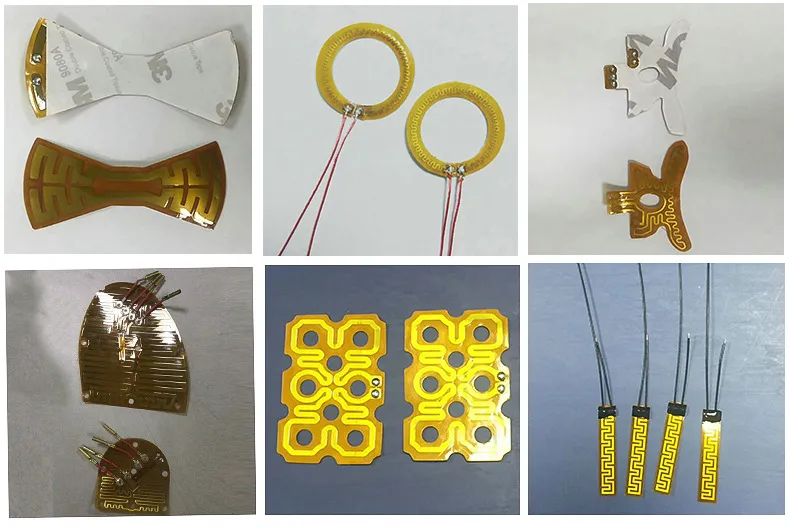

Dimension(L*W*H):custom

Weight:0.01 KG

Voltage:3.7-220V

Warranty:1 Year

Working Temperature Range:-30 – 200 ℃

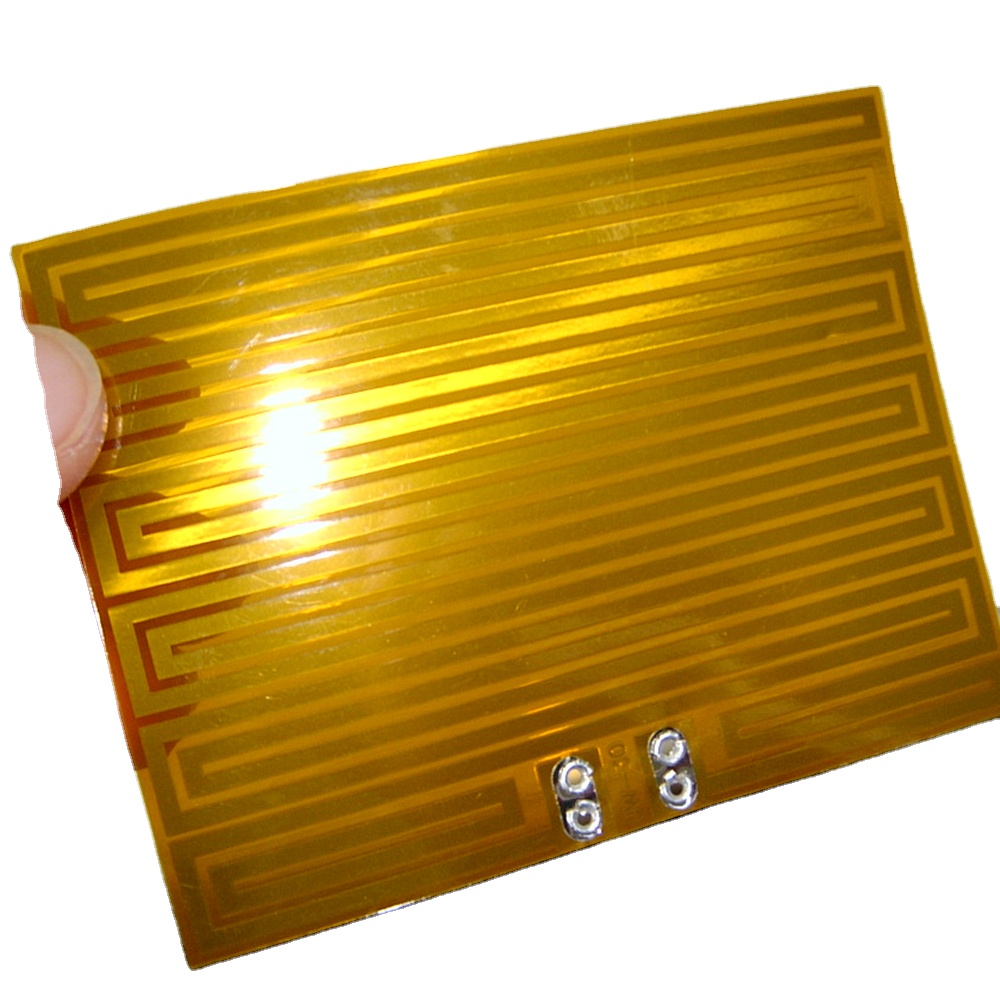

Material:Polyimide film+etched metal foil

Size:Customized custom,Max 300*1400mm,mini 10*10/3*280mm

Thickness:0.18-0.226mm

Back adhesive:3M 467 / 468 or customized

Power deviation:5%-10%

Supply Ability:10000 Piece/Pieces per Week

Packaging Details:PE inner bag+Carton

Certificates:CE,RoHS

What is a 12V PI /Polyimide Heater?

A 12V PI (Polyimide) heater is a type of heating element that operates at 12 volts DC. It is made of a thin, flexible Polyimide film coated with a conductive metal layer that generates heat when an electrical current passes through it. The heater’s size and specifications, including its power density, operating temperature range, resistance, and thickness, can be customized to meet specific heating requirements for various applications. The 12V PI heater is commonly used in a range of industrial, commercial, and consumer applications, such as automotive, aerospace, medical, and electronic devices, where space and weight are a concern and where a low voltage heating solution is required.

How does 12V PI/Polyimide Heater Work?

A 12V PI (Polyimide) heater works by converting electrical energy into heat energy. It consists of a thin, flexible Polyimide film coated with a conductive metal layer, such as copper or nickel, that generates heat when an electrical current is applied. The metal layer’s resistance causes it to heat up as electrical current passes through it, and the Polyimide film provides insulation and flexibility.

The 12V PI heater operates at a low voltage, which is safer and more efficient than higher voltage heating elements. The heater’s power output and temperature are determined by several factors, including the resistance of the metal layer, the size and shape of the heater, and the operating voltage.

The 12V PI heater is commonly used in applications that require a low-profile, lightweight, and flexible heating solution, such as in aerospace, automotive, medical, and electronic devices. The heater’s size and specifications can be customized to meet specific heating requirements for various applications, making it a versatile and efficient heating solution.

What are the Applications of a 12V Pi/Polyimide Heater?

The 12V PI (Polyimide) heater has a wide range of applications in various industries, including:

- Aerospace: The 12V PI heater can be used in aircraft and spacecraft for de-icing, anti-icing, and temperature control applications.

- Automotive: The 12V PI heater can be used in automotive applications, such as seat heating, mirror defrosting, and engine compartment heating.

- Medical: The 12V PI heater can be used in medical applications, such as warming blankets, medical equipment, and diagnostic devices.

- Electronics: The 12V PI heater can be used in electronic devices, such as LCD displays, battery heaters, and camera lens heaters.

- Food and Beverage: The 12V PI heater can be used in food and beverage applications, such as warming trays, coffee makers, and vending machines.

- Industrial: The 12V PI heater can be used in industrial applications, such as heating pipes, tanks, and vessels, as well as for freeze protection.

- Consumer Goods: The 12V PI heater can be used in consumer goods, such as heated clothing, footwear, and blankets.

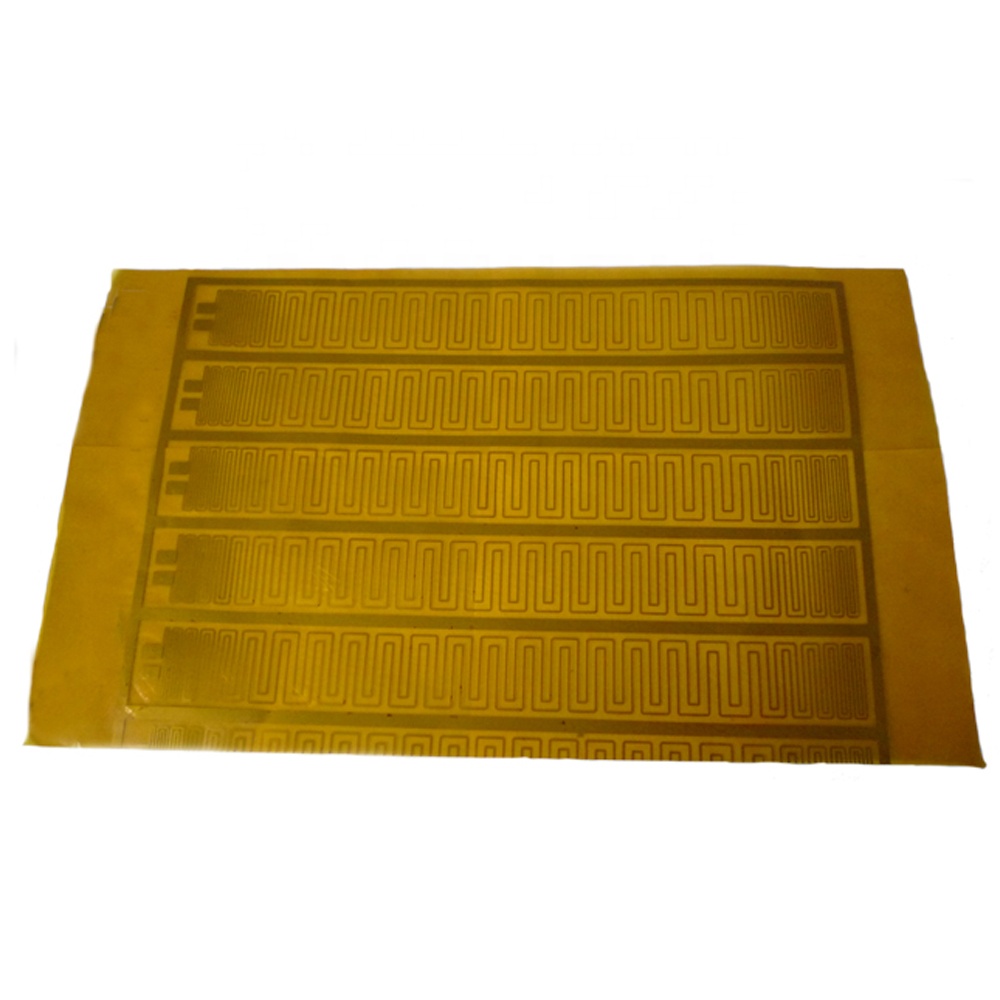

What are the process to manufacturer the PI/Polyimide heaters?

- Designing the Heater: The first step in manufacturing a PI heater is to design the heater’s dimensions, power output, resistance, and operating temperature range. This involves selecting the appropriate materials and determining the heater’s configuration, such as the size and shape of the heating element and the number of circuits.

- Cutting the Polyimide Film: The Polyimide film is cut to the required size and shape using a computer-controlled cutting machine. The film’s thickness is carefully controlled to ensure that it is consistent throughout the heater.

- Applying the Metal Layer: A conductive metal layer, such as copper or nickel, is applied to the Polyimide film using a deposition technique, such as sputtering or vapor deposition. The metal layer’s thickness is carefully controlled to achieve the desired resistance and power output.

- Etching the Metal Layer: The metal layer is then etched to create the desired circuit pattern using a photolithography process. This involves applying a photosensitive layer to the metal layer and exposing it to UV light through a mask. The unexposed areas are then removed using a chemical solution, leaving behind the desired circuit pattern.

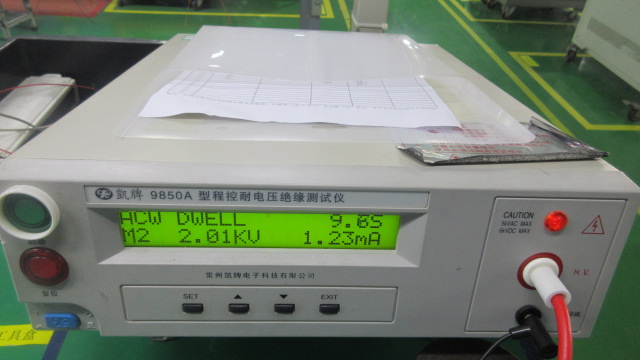

- Testing the Heater: The heater is then tested to ensure that it meets the required specifications, including its resistance, power output, and operating temperature range. The heater is also tested for reliability and durability to ensure that it can withstand repeated use and environmental conditions.

- Mounting the Heater: The heater is mounted onto a substrate, such as a metal plate or a flexible film, using a pressure-sensitive adhesive. The substrate provides mechanical support and can also improve the heater’s thermal conductivity.

- Final Testing: The heater is finally tested again to ensure that it functions correctly and meets all the required specifications. The heater is then packaged and shipped to the customer.

|

Product

|

|

|

Voltage Range

|

1.5v~400v

|

|

Power Density Range

|

0.03w/cm2~1.5w/cm2

|

|

Heater Size

|

3mm~500mm

|

|

Insulation Material

|

Polyimide Film

|

|

Heating Material

|

Etched metal foil

|

|

Thickness

|

0.15mm~0.3mm

|

|

Temperature range

|

-30℃–290℃

|

|

Cable conductor

|

Silicone insulated leads

|

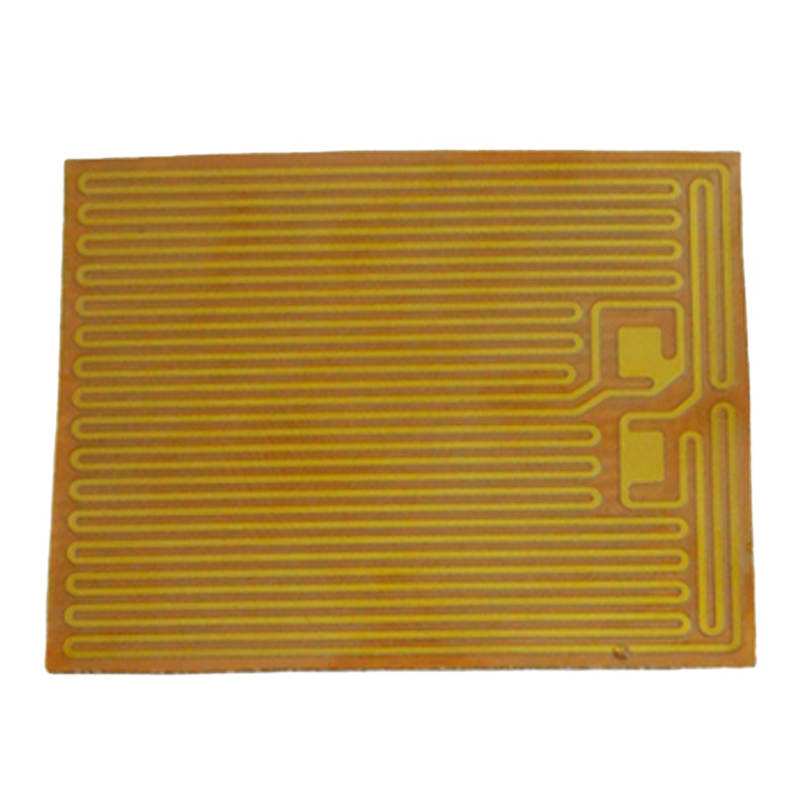

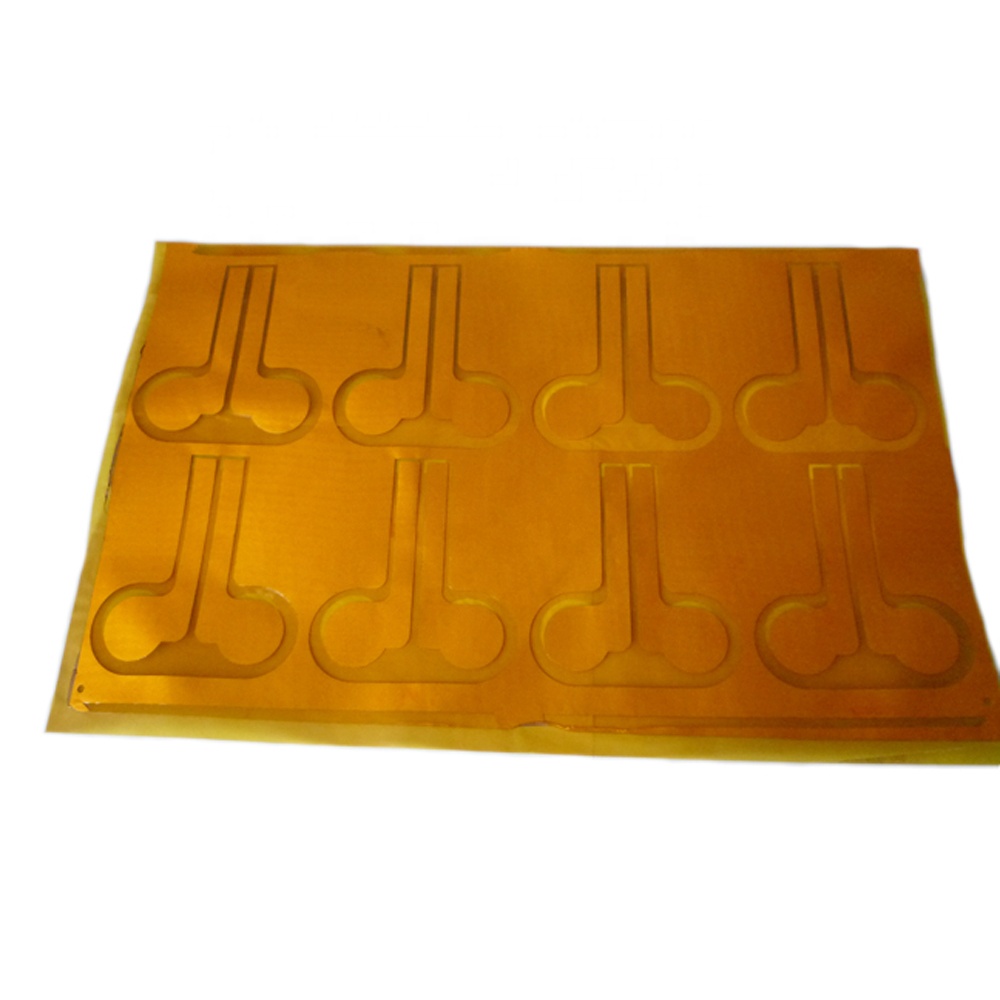

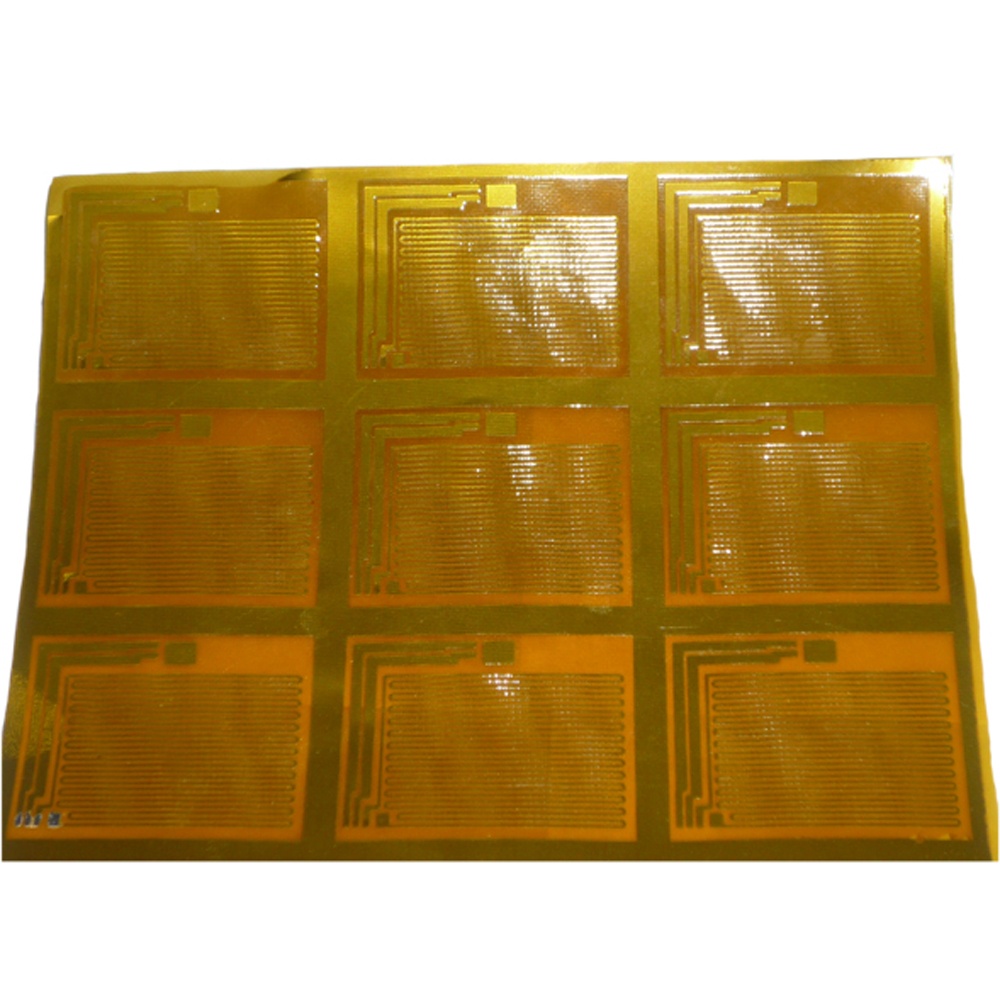

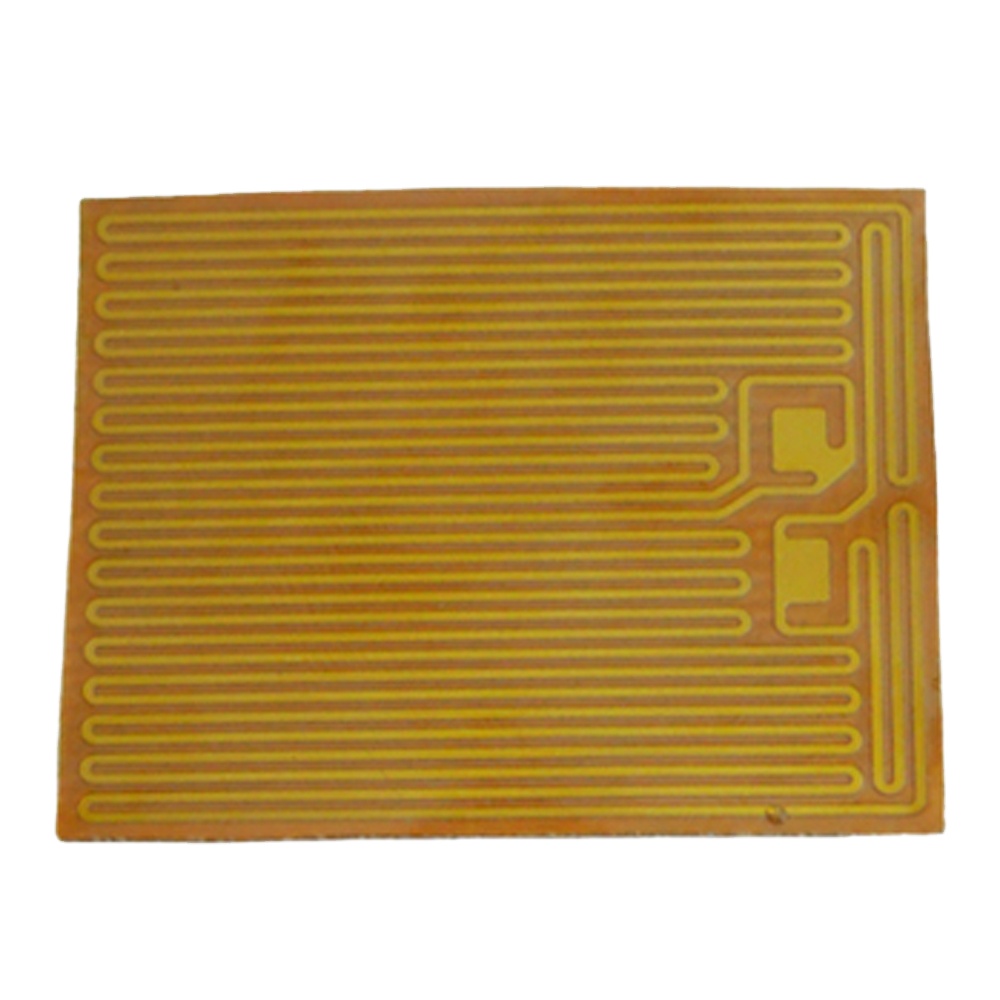

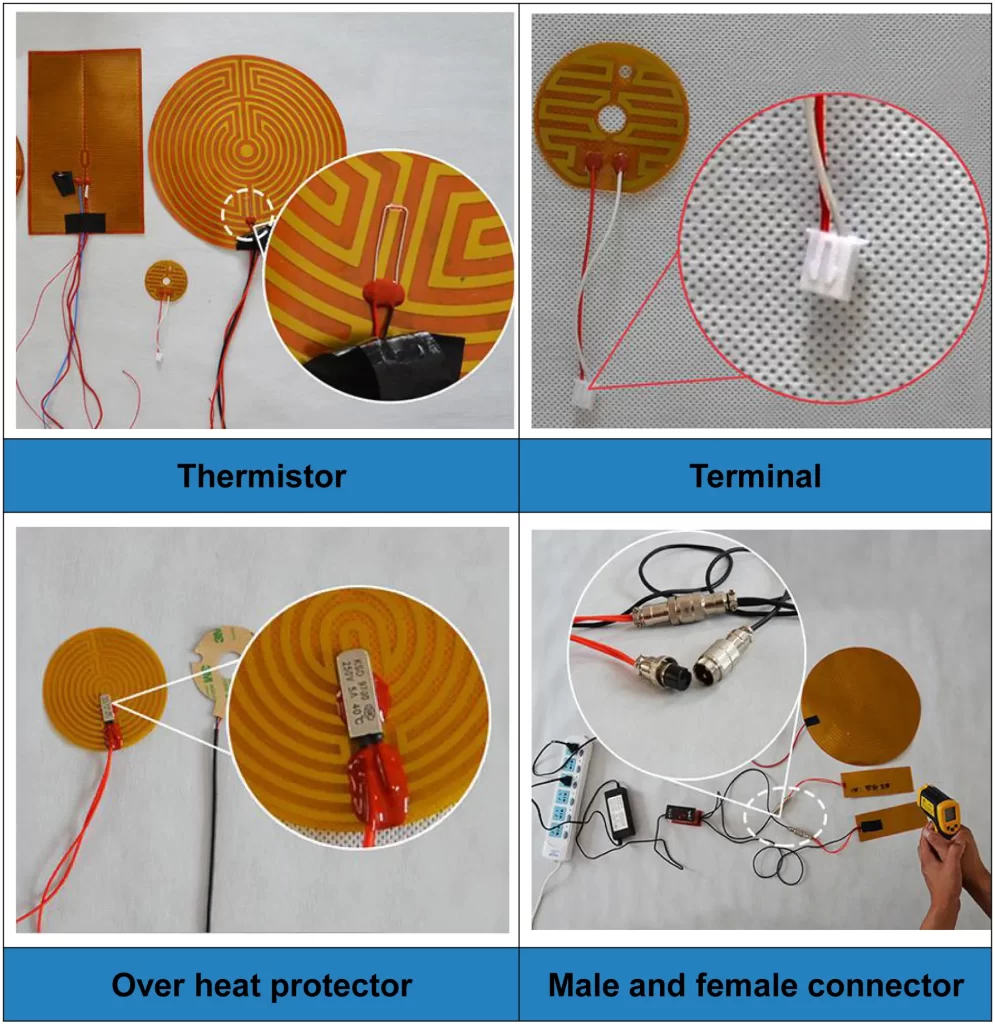

Configuration of the PI heater

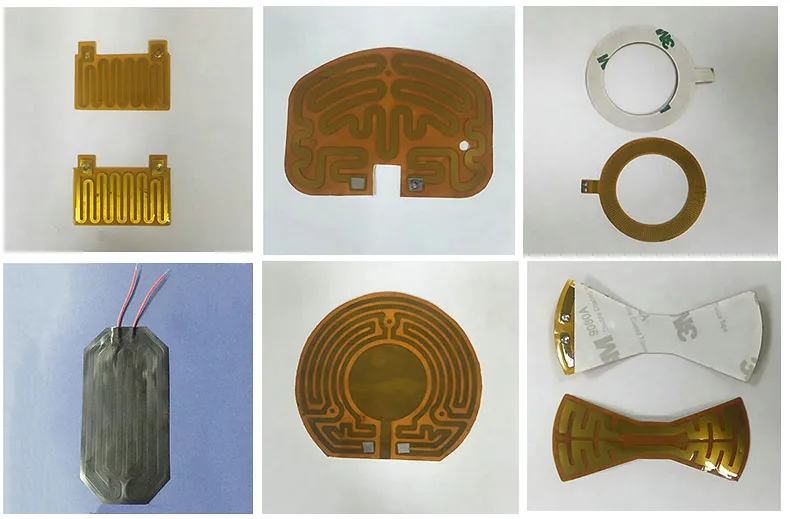

PI heater in different shapes

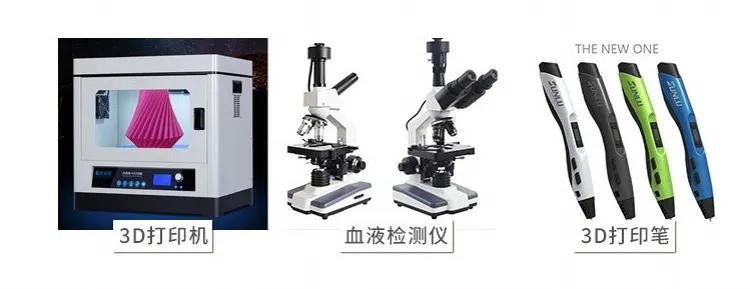

PI heater Application

Our Factory

Shenzhen Excellent Hengxin Technology Development Co.,Ltd was established in 2002,our main products are Polyimide/Kapton heaters,PET heater ,Silicone heater,PTC heater and MCH with customized size and shape, with qualified products and sustained relationship with clients,we grow quickly and till now our manufacturing area is 3100 ㎡ with 4 production lines and 32 production machines.In year 2022,our export revenue have made a breakthrough for 6 million US Dollars. Over 100,000 pcs heaters can be made monthly with customized requirement.All of our material composed for the heaters have gained CE certificates.

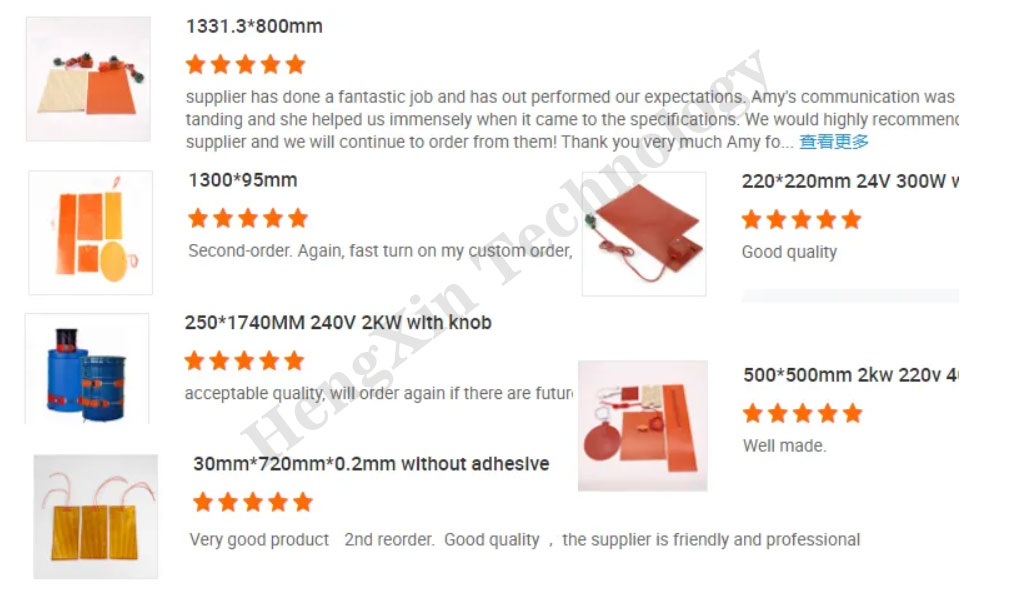

Customers Feedback for our products

Certificates of the heating elements

Other products you may interest:

PI Heater is at the forefront of the heating industry, providing energy-efficient heating solutions for modern industries. Our heating solutions, including infrared heaters, radiant heaters, and heating elements, are designed with temperature control technology to ensure precision and accuracy. We understand the importance of energy efficiency, which is why we strive to create heating solutions that are eco-friendly and reduce energy consumption. With our innovative products and advanced technology, we’re revolutionizing the way industries heat their facilities. PI Heaters is dedicated to providing top-of-the-line heating solutions that are reliable, efficient, and effective. Join us and choose PI Heaters for all your heating needs,our warranty for the Pi heaters manufactured is 50,000 hours in normal working environment and we have different connector and temperature control for your option.

Contact us now freely if you have any demand ,our team will get back to you within 2 hours during work-days.